OEM ODM Automatic Double side Linear Type Labeling Sticker Packing Machine

Description

The Automatic Double Side Linear Type Labeling Sticker Packing Machine is an efficient and versatile solution for labeling various bottle types, including round, conical, square, flat, and oval bottles. This state-of-the-art machine is designed to ensure precision in double-sided labeling with unmatched speed and reliability, making it an essential asset for production lines in industries such as food, pharmaceuticals, and chemicals.

Featuring advanced mechanical systems and programming controls from renowned brands, it operates within stringent accuracy limits of ± 1mm, ensuring consistent quality. The machine’s robust construction with 304 stainless steel and aluminum alloy materials guarantees durability and adherence to GMP standards.

Whether used as a standalone unit or integrated into a production line, this labeling machine maximizes efficiency, with capabilities of labeling up to 4000 bottles per hour (BPH). Its customizable label dimensions cater to various product requirements, making it an excellent choice for any manufacturing setting.

Specifications

| Feature | Specification |

|---|---|

| Accuracy | ± 1.5mm |

| Inner Diameter | 76mm |

| Outer Diameter | 380mm |

| Label Width | 10-110mm (customizable) |

| Label Length | 20-360mm |

| Capability | 3000-4000 BPH |

| Power Supply | 220V, 50HZ |

| Installed Power | 3500W |

| Weight | 450KG |

| Dimensions | 2600 * 1400 * 1600mm |

Additional Information

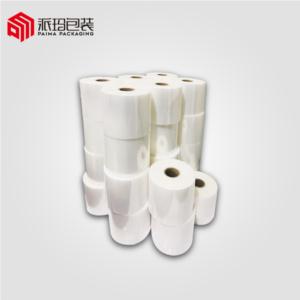

This double-sided labeling machine requires a backing paper of 62g white glassine, which is dense and strong. Key specifications for the backing paper include:

- Basic Weight: 62g/㎡ ± 5%

- Thickness: 55μm ± 5%

- Anti-tensile Force (Machine Direction): 16kg/25mm

- Horizontal: 7kg/25mm

- Tear Resistance (Machine Direction): 25g/sheet

- Horizontal: 31g/sheet

- Transparency: 52%

This machine is equipped with advanced components such as a PLC from Siemens, touch screen interface from WEINVIEW, and other high-quality parts ensuring stability and efficiency in operation. The labeling machine is designed to be user-friendly while maintaining a high level of performance.