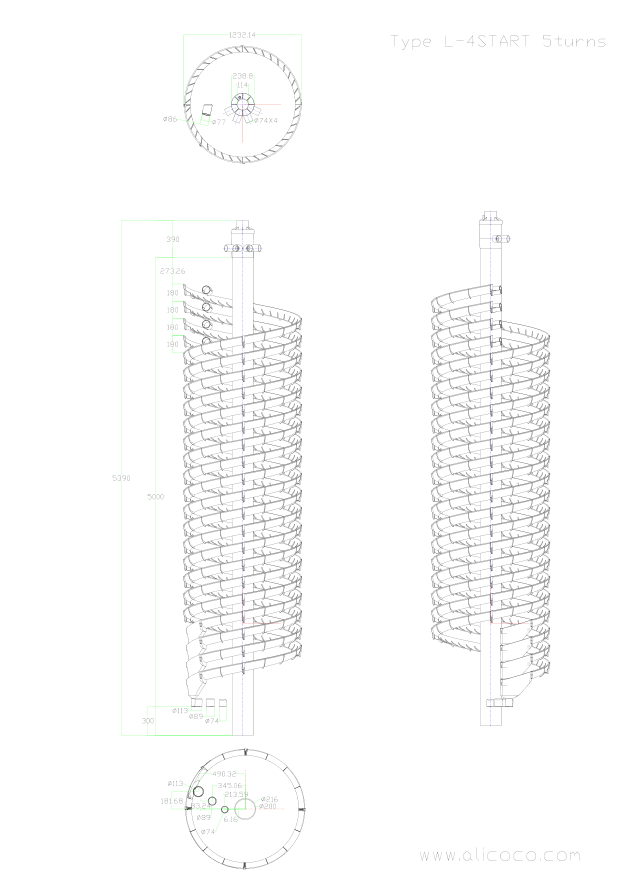

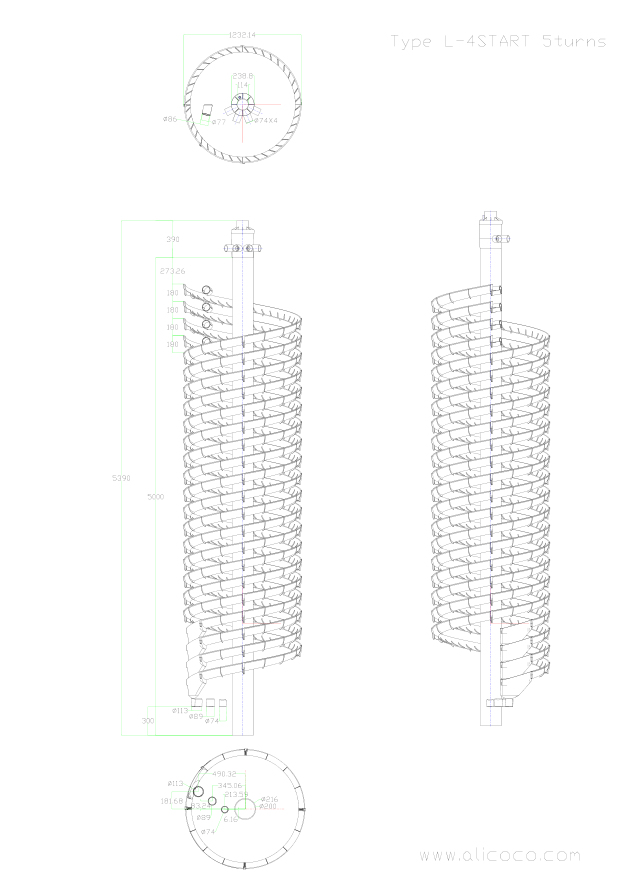

OEM ODM spiral concentrator Type L

Description

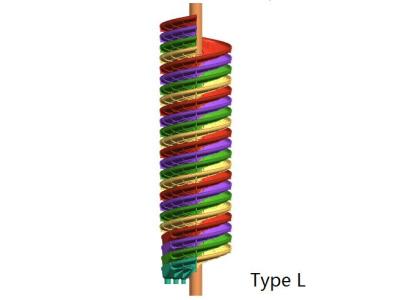

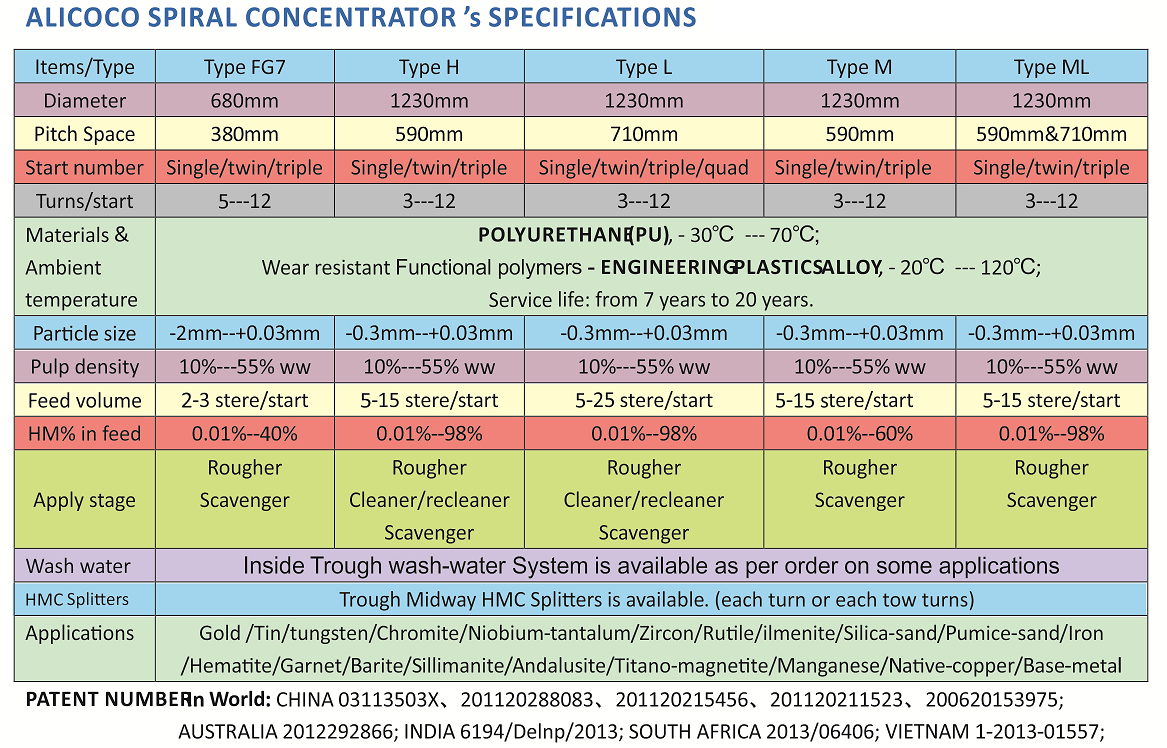

The spiral concentrator Type L is a cutting-edge solution for gravity separation, designed to provide exceptional performance and reliability in various mineral processing applications. As a leader in spiral technology, this concentrator offers unparalleled confidence in the efficiency of gravity separation circuits. Manufactured in the world’s largest spiral facility located in Australia, it boasts an impressive production capacity of over 20,000 starts annually. This advanced equipment is tailored for diverse applications, including rutile, ilmenite, and zircon concentration, iron ore beneficiation, and more.

With features such as a replaceable modular cast polyurethane feed box, optimized splitter configurations, and an integrated engaged launder system, the spiral concentrator Type L promises a longer service life and enhanced recovery rates. The design simplifies process circuits, reducing capital costs while maintaining high separation efficiency.

Specifications

| Feature | Description |

|---|---|

| Feed Box | Replaceable modular cast polyurethane |

| Splitter Configuration | Designed for each application |

| Concentrate Diverter | High concentrate product grade |

| Re-pulping Devices | Enhances recovery and grade |

| Product Collector Box | Cast polyurethane ensuring long life |

| Launder System | Integrated engaged system |

| Feed Distribution | Accurate top or bottom entry |

| Wash-water Availability | Available with or without |

Additional Information

This spiral concentrator is available in various configurations, including single, twin, triple, and quad troughs to meet specific capacity requirements. With the capability of establishing spiral banks up to 48 starts, it maximizes capacity while minimizing floor space. The equipment is designed for low maintenance and operational costs, ensuring a long operating life with consistent separation efficiency.