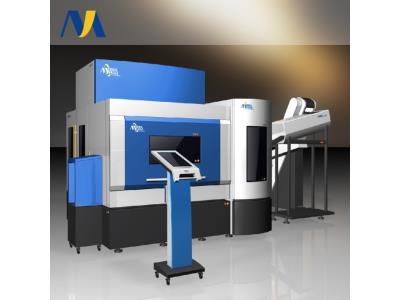

OEM ODM MG-SS Series Automatic Blow Molding machines

Description

The MG-SS Series Automatic Blow Molding Machines by MEGA Machinery are engineered for efficiency and versatility in the production of PET bottles. With decades of design and manufacturing experience, these machines cater to a broad spectrum of industrial applications, producing bottles ranging from a tiny 0.1 liter to a substantial 5 gallons. The MG-SS Series is crafted to significantly reduce operational costs while enhancing productivity, making it the ideal choice for competitive bottling markets.

Designed with a focus on user-friendly operation, the MG-SS series employs a patented process by GM Mr. Cai Yunsen, which optimizes performance by spacing the preforms effectively. The machine achieves a remarkable maximum output of 1500 bottles per hour (BPH) for single cavity operations, and an impressive energy cost reduction of up to 30% compared to traditional systems.

Specifications

| Feature | Description |

|---|---|

| Output Capacity | Up to 4500 bottles per hour for 0.1L volume using four-cavity blow mold |

| Controller | Delta PLC controller with self-diagnosis and friendly touch interface |

| Clamping Unit | Cast molded platen with toggle clamping unit for enhanced stability and speed |

| Heating System | Zoned and layered infrared heating system for uniform temperature control |

| Stretching System | Double cylinder unit for rapid and efficient stretching |

| Preform Loading System | Automatic loading with minimal moving parts for reliability |

Additional Information

- Suitable for producing 0.1 to 2.5L standard neck PET containers

- Built-in memory of the PLC to store production settings

- Equipped with a special air storage unit for efficiency

- Compact design to optimize space usage

- Simple installation and startup operations

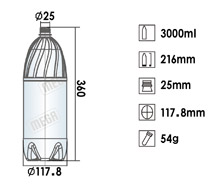

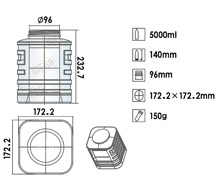

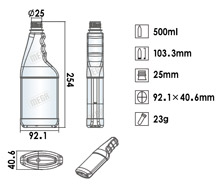

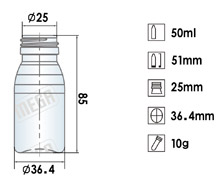

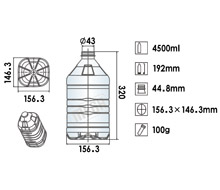

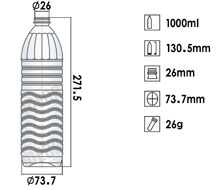

Bottle Samples