OEM ODM CNC Shearing Center

Description

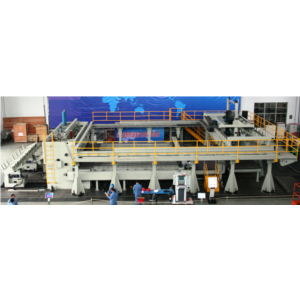

The CNC Shearing Center, model RD-QC11K-16×12000, is a robust and advanced cutting machine designed for precision shearing. With an extensive working table, this machine combines rigidity and high strength with flexible manufacturing capabilities. It offers full automation, ensuring high precision and efficiency that surpasses conventional shearing machines. The CNC Shearing Center can compensate for stress deformation in plates, providing unmatched accuracy in material processing.

This sophisticated machine can be efficiently operated by a single operator, facilitating all stages from loading the plates, side shearing, and main shearing to support, outlet feeding, and stacking with complete automatic control. The CNC system manages all programming and operational tasks, accessible via a user-friendly control panel.

The center integrates various components, including a main shear machine, an auxiliary sheet preparation trolley, an electromagnetic chuck loading machine, and an advanced hydraulic and electrical system, ensuring a comprehensive and efficient shearing process.

Specifications

| Attribute | Detail |

|---|---|

| Max. Shearing Thickness (mm) | 16 |

| Max. Shearing Length (mm) | 12000 |

| Shear Angle (°) | 1.5-2.5 |

| Strokes (n/min) | 4-8 |

| Back Gauge Range (mm) | 20-800 |

| Motor Power (kW) | 55 |

| Overall Dimensions (L*W*H) | 16880*13600*7150 |

Additional Information

Main Configuration:

– Main electric components: Schneider

– Frequency converter, servo motor: YASKAWA, Japan

– CNC system: Siemens

– Stroke switch: Omron

– Oil pump: NACHI, Japan

– Hydraulic valves: Huade, Beijing

– Ball screw: Hiwin, Taiwan

– Power supply: 380 Volts/3 Phases/50Hz

Options:

– Side shear