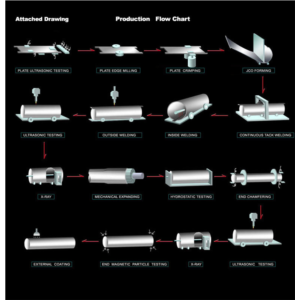

OEM ODM Longitudinal Seam Submerged Arc Welding pipe plant in JCOE forming method

Description

The Longitudinal Seam Submerged Arc Welding (LSAW) pipe plant utilizes the advanced JCOE forming method to manufacture high-quality large diameter pipes. This state-of-the-art facility is designed for efficiency and precision, making it an essential asset in various industries including oil and gas, water supply, heat supply, coal, mine slurry, paper production, and construction. The technology facilitates the creation of submerged arc welded pipes with a high degree of accuracy and is capable of producing a range of pipe specifications to meet the stringent requirements of modern engineering applications.

Specifications

| Specification | Details |

|---|---|

| Plate Width | 1,490~4,500 mm |

| Wall Thickness Range | 8~40 mm |

| Max. Plate Length | 12,300 mm |

| Max. Plate Weight | 17.5 t |

| Pipe Outside Diameter | ф406~ф1524 mm |

| Pipe Length | 8000-12200 mm |

| Typical Steel Grade | X42-X80, Q345 |

| Applicable Standards | ISO3183-3, API 5L Spec. 5L, GB/T9711.1, GB/T9711.2 |

| Forming Method | JCOE |

| Pipe Accuracy | Out-of-roundness Tolerance ±1%; Straightness Deviation ≤0.2% |

| Production Capacity | 120,000~150,000 t/a |

Additional Information

For optimal performance, regular maintenance of the LSAW pipe plant is recommended. Ensure that all machines are calibrated correctly to maintain the required tolerances. The production line includes specialized machines such as plate edge milling machines, crimping presses, and pipe forming presses, each designed for efficient operation and high-quality output.