Description

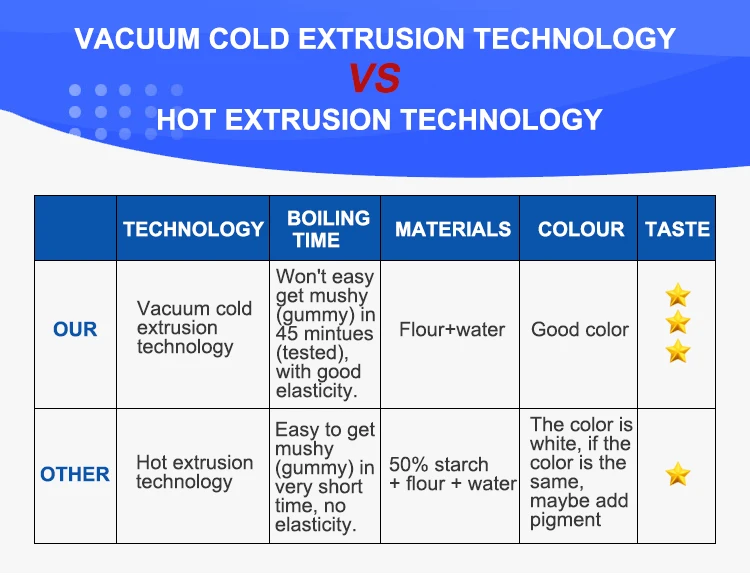

The 100-600kg/h short cut macaroni pasta production line is an advanced piece of equipment designed to efficiently produce various shapes of macaroni pasta using high-quality wheat flour and durum semolina. This production line utilizes vacuum cold extrusion technology, ensuring a superior texture and taste. By simply changing the dies in the extruder, you can create an array of pasta shapes such as tubes, elbows, screws, and shells. The dies are imported from Italy, crafted from copper with a Teflon inner layer for enhanced durability and product quality.

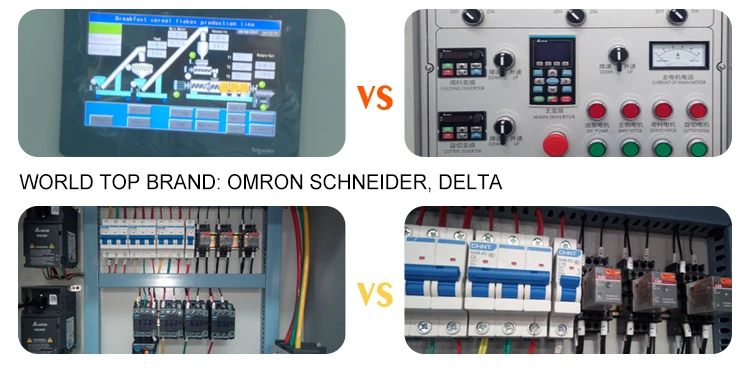

Key features include a robust PLC control system and a stainless steel construction, ensuring longevity and ease of maintenance. With a warranty period of 2 years, this production line not only guarantees quality but also exceptional service, including recipe provision and on-site installation training by our experienced engineers.

Specifications

| Model | Installed Power | Consumption Power | Output | Host Size |

|---|---|---|---|---|

| TXF-100 | 35kw | 21kw | 80-100kg/h | 2.2×0.8×1.8m |

| TXF-200 | 50kw | 37kw | 200kg/h | 3.9×2.8×4.5m |

| TXF-300 | 60kw | 45kw | 300kg/h | 4.5×3.5×4.5m |

Additional Information

This production line features a vacuum feeding system that automatically conveys flour to the storage hopper. The mixing and extrusion processes occur under vacuum conditions, enhancing the quality of the pasta. The cutting system is adjustable for speed, and the vacuum creation system is composed of essential components for optimal operation.

Moreover, the automatic water supply system ensures precise water management during production. The equipment is designed with energy efficiency in mind, achieving significant energy savings while maintaining high production standards.