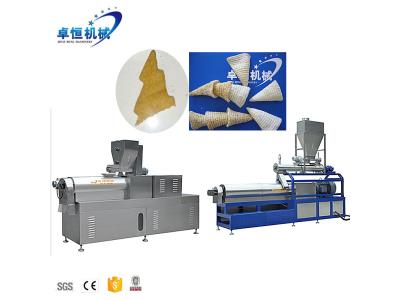

The frying snack food production line is designed for the efficient production of a variety of fried snacks, including bugle chips, salad chips, salad flakes, fish-shaped snacks, and tortilla corn chips. By changing the dies in the extruder and shaping machines, users can create snacks in different shapes and sizes. This production line utilizes advanced Twin-screw Extrusion technology, ensuring high-quality output and operational efficiency. Its main components are sourced from reputable brands, including Siemens for the main motor and ABB for relays, ensuring reliability and performance. The machine comes with a warranty period of 2 years, providing peace of mind for users.

| Attribute | Details |

|---|---|

| Capacity | 120-250kg/h |

| Power Supply | Based on 380V 50 Hz 3 phase (customizable) |

| Machine Details | Stainless steel: 201, 304, 316 (on request); Electric parts: ABB, Delta, Fuji, Omron, Siemens (customizable) |

| Certificate | CE, ISO, SGS, BV, Supplier Assessment |

| Raw Material | Cereals (corn, wheat, oat, barley, rice, etc.) and mixtures of grains |

| Product Type | Bugle chips, Doritos corn chips, rice crust, etc. (customizable shapes) |

| Formula | Basic formula provided; assistance in developing new formulas available |

| Model | Installed Power | Real Power | Capacity | Dimension |

|---|---|---|---|---|

| ZH65 | 35 KW | 22 KW | 120-150kg/h | 39000x1200x2200mm |

| ZH70 | 50 KW | 37 KW | 200-250kg/h | 41000x1500x2200mm |

The production process involves a series of steps: Mixing System → Extrusion System → Shaping Machine → Frying Line → Flavoring Line → Cooling Line.