Description

The 150-2000kg/h Pet Food Production Line is a versatile and efficient system designed to create various shapes and sizes of pet food, suitable for both dogs and cats. By simply changing the dies in the extruder, manufacturers can produce a wide range of textures, flavors, and colors, ensuring high-quality, tasty, and nutritional options for pets. This production line features renowned components such as a Siemens main motor and ABB relays, guaranteeing reliability and performance. With a warranty period of 2 years, this line offers professional production capabilities at an affordable price, making it an excellent investment for pet food manufacturers.

Professional production, quality assurance, affordable, welcome to inquire. 100% factory direct sales, look forward to building cooperation with you wholeheartedly!

Specifications

| Model | Installed Power | Real Power | Output | Dimension |

|---|---|---|---|---|

| ZH65 | 35 kw | 22 kw | 150 kg/h | 39000 x 1200 x 2200 mm |

| ZH70 | 50 kw | 37 kw | 250 kg/h | 41000 x 1500 x 2200 mm |

| ZH85 | 110 kw | 75 kw | 500 kg/h | 43000 x 3500 x 4300 mm |

| ZH95 | 151 kw | 110 kw | 1 ton/h | 4700 x 1900 x 4800 mm |

| ZH135 | 425 kw | 335 kw | 3 ton/h | 5200 x 2000 x 4800 mm |

Additional Information

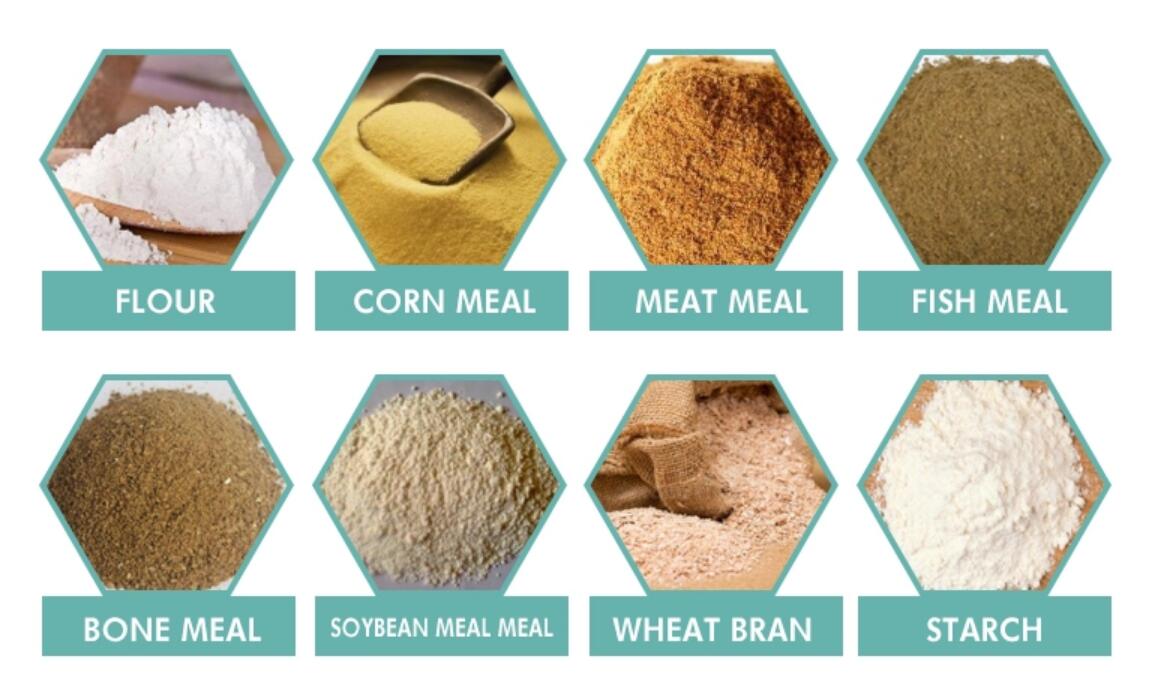

The production line is designed for a variety of raw materials including rice flour, corn flour, wheat flour, low-temperature soya flakes meal, rice bran, wheat bran, fish powder, and bone powder. This flexibility allows manufacturers to tailor their pet food products according to market demands.

Process Flow Chart:

Mixing system – Extrusion system – Drying system – Flavoring line – Cooling line – Packing machine

Packaging & Shipping

Machines are wrapped completely and safely in film, then packed in strong fumigation-free cases or 20’/40′ containers for delivery. We ensure the utmost care for each machine during shipping, which takes 20-30 working days after receiving advance payment.