Description

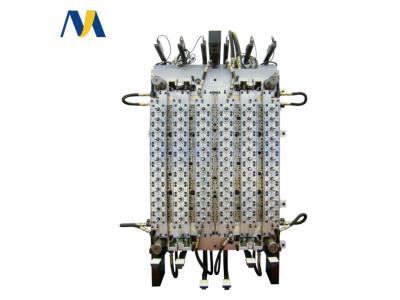

The 72 Cavity Preform Mould for PCO 1810 neck finish is expertly engineered for producing preforms specifically designed for Carbonated Soft Drinks (CSD). This advanced mould features a balanced hot runner system with a shut-off valve gate, ensuring optimal performance without any stringing during the injection molding process. Mega, a leading manufacturer in China, delivers precision and efficiency with this mould, making it an ideal choice for high-demand production environments.

With the ability to accommodate up to 72 cavities, this mould offers remarkable productivity for preforms weighing 25g. The innovative design not only reduces power consumption but also minimizes the tonnage required for molding systems. Additionally, it integrates advanced features like a cam roller design for easy maintenance, enhancing its usability for operators.

Whether you’re producing thick wall preforms for 5-gallon containers or standard preforms for bottled beverages, this mould is versatile enough to meet various industrial needs.

Specifications

| PET Preform Mould Specification | |

| Mould Name | 72 cavity preform mould for PCO 1810 Neck 25g Preform |

| Mould Cavity | 72 cavity |

| Neck Finish | PCO 1810 CSD Neck finish |

| Preform Weight | 25g |

| Insert Materials | 2316 stainless steel from Germany |

| Mould Body | P20 steel material |

| Cycle Time | 32 sec with general PET screw type of injection molding machine |

| Cycle Time with Two Stage Injection and Post Cooling System | 17 sec with 3 stage post cooling system |

| Hot Runner Design | Balanced hot runner with valve gate system |

| Suitable Injection Molding Machines | Husky, Netstal PET line, PET Master, General PET injection molding machine |

Additional Information

MEGA also provides refurbishment services for preform moulds and can assist with weight and neck finish conversions for other brands, ensuring that your production needs are met comprehensively.