Description

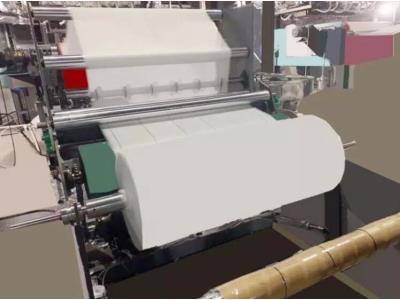

The AF-600mm PP Melt Blown Non Woven Fabric Machine is a state-of-the-art solution for producing high-quality meltblown fabrics. With over a decade of experience in manufacturing meltblown fabric machines, this model utilizes polypropylene as its primary material, enabling it to create ultra-fine fibers ranging from 1 to 5 microns in diameter. The unique capillary structure of the microfiber enhances the filtering, shielding, insulation, and oil absorption capabilities of the meltblown cloth, making it ideal for various applications including air and liquid filtration, isolation materials, absorption materials, and wiping cloths.

Working Principle: The machine works by feeding polypropylene into a single screw extruder that melts the polymer. Using high-speed hot air, the polymer is stretched into very fine fibers which then form a network on a porous surface. The fibers bond together to create a durable non-woven fabric.

Specifications

| Attribute | Details |

|---|---|

| Raw Material | 100% New Polypropylene |

| Fiber Micro | 15-30μm |

| Fabric Width | 525mm |

| Fabric Weight | 15-100gsm |

| Fabric Thickness | 2-5mm |

| Production Capacity | 180-200kg/day |

| Actual Running | 20-25KWH |

| Total Installed | 40-60kw 380v |

| Mold Width | 600 mm |

| Mole Hole Size | 0.2-0.4mm (can be customized) |

Additional Information

Features:

- The whole line is well-structured and easy to operate.

- Highly automated system for efficient production.

- Control elements are from well-known manufacturers, ensuring high performance and reliability.

- PLC controlled with a user-friendly touch screen interface.

- Customizable design and configuration based on customer requirements.

Working Process:

Flow Chart: Raw Material (Edge Material Recycling) – Melt Extrusion – Meltblow Device – Web Forming Machine – Winding and Slitting Machine – Finished Products.