Description

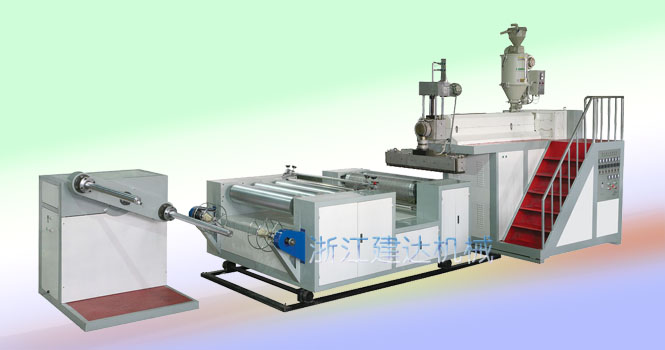

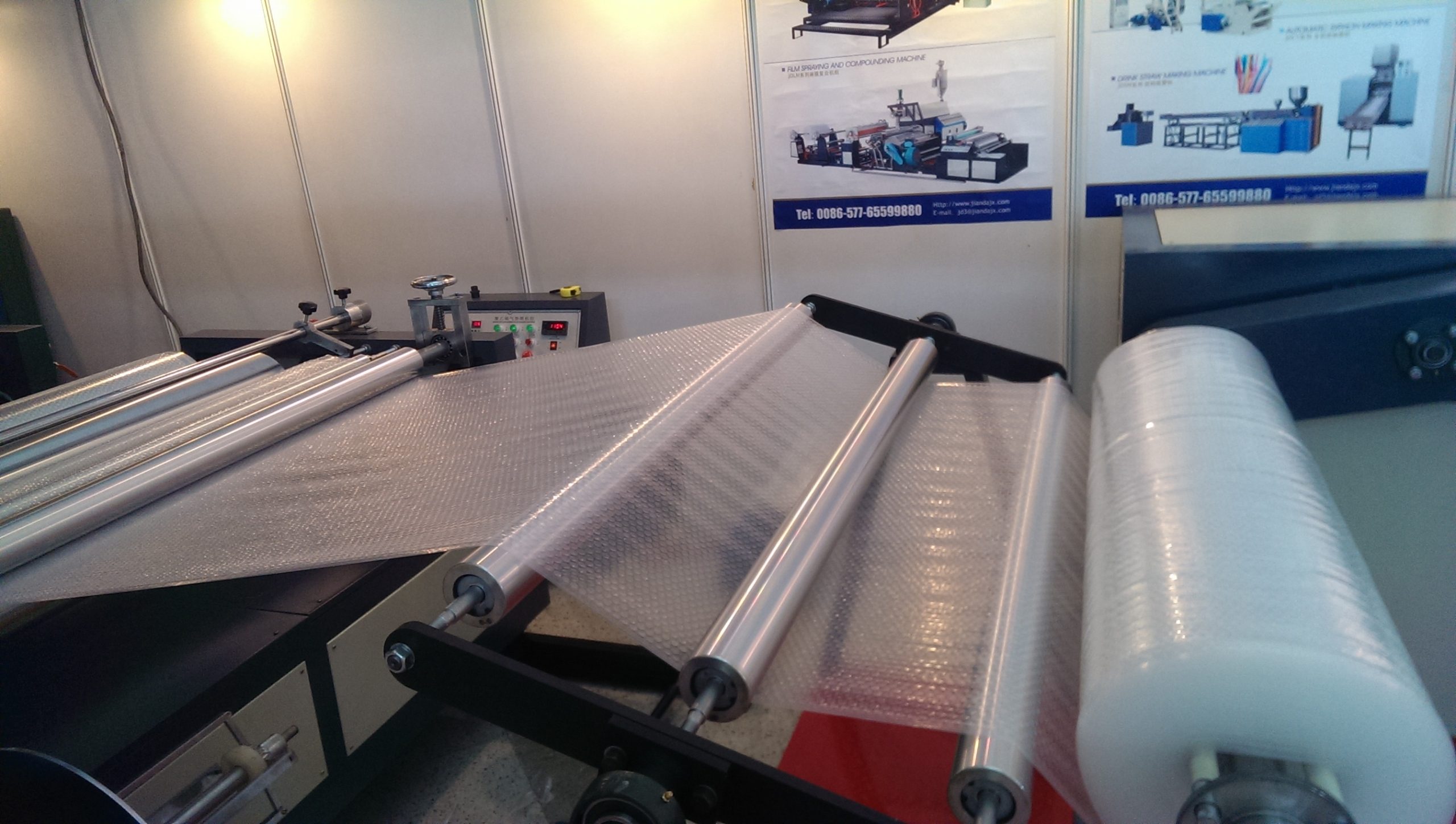

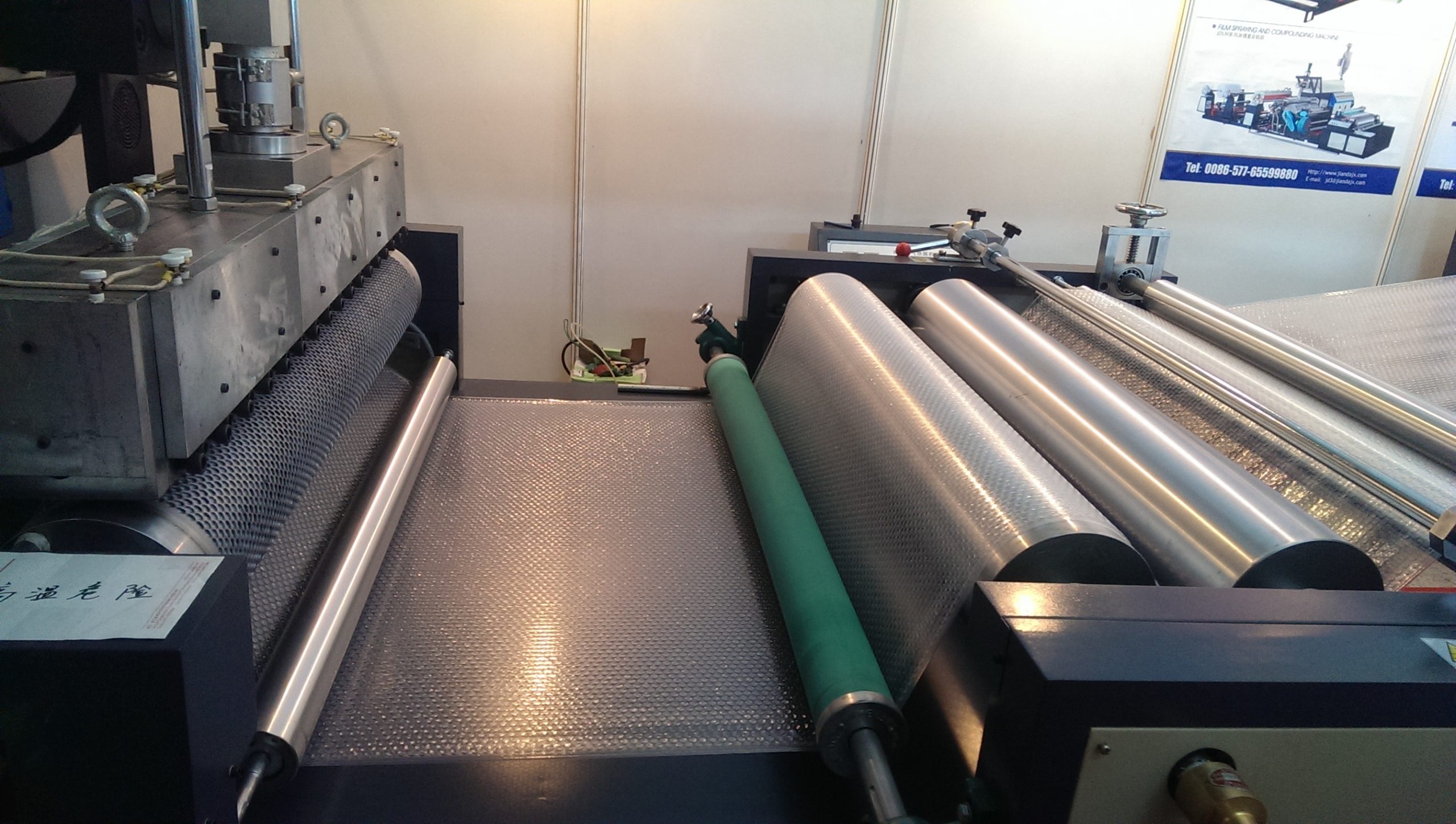

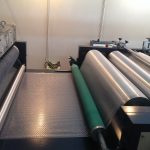

This air bubble film making machine is engineered to produce 2-layer polyethylene air bubble film sheets. Ideal for a variety of packing needs, it excels in household wares packing, post parcel packing, precise instruments packing, bicycle packing, and even furniture packing. The machine is composed of six essential parts: the main extruder part, filter part, T-die part, air bubble film forming roller part, traction part, and the winding part, ensuring efficient and reliable production.

Specifications

| Model | JD PE-1000 | JD PE-1200 | JD PE-1600 | JD PE-2000 |

|---|---|---|---|---|

| Screw Diameter | Φ65mm | Φ70mm | Φ80mm | Φ90mm |

| Finished Film Width | 1000mm | 1200mm | 1500mm | 2000mm |

| Output | 55kg/h | 75kg/h | 110kg/h | 150kg/h |

| Main Motor Power | 18.5kw | 22kw | 30kw | 45kw |

| Total Power | 48kw | 55kw | 70kw | 105kw |

| Machine Weight | 4000kg | 4200kg | 4500kg | 7000kg |

| Overall Dimensions | 9.0m × 3.5m × 2.5m | 9.5m × 3.8m × 2.5m | 10m × 4.0m × 2.6m | 11.5m × 4.8m × 4.0m |

| Power Supply | 380/3/4/50 (Volt/Ph/Line/Hz) | |||

Additional Information

For optimal performance, ensure the machine is set up according to the manufacturer’s specifications regarding power supply and dimensions. Regular maintenance is recommended to keep the machine in peak working condition.