Description

The Air Cushion Conveyor is an innovative and efficient solution for transporting bulk materials, especially grains, in various industries including food processing, grain terminals, mining, coal, chemical, and steel. Designed with a low self-structure weight and high conveying capacity, this conveyor minimizes the load on silo roofs while maximizing performance.

Utilizing a unique air-cushion belt mechanism that replaces traditional rollers, it significantly enhances operational conditions by reducing frictional resistance. The fully-enclosed design ensures minimal dust emission and low noise levels, making it an environmentally friendly option.

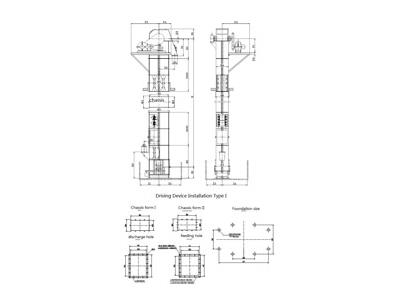

Available in both single and double chamber configurations to meet specific operational needs, the conveyor features a tail equipped with a sealing-type self-cleaning feed recycle device, effectively addressing material accumulation issues. Additionally, it includes inspection doors, observation windows, and a dust-collection exhaust inlet to facilitate monitoring of equipment status.

To further enhance safety and efficiency, optional features such as speed detection, misalignment alerts, anti-blockage systems, and scram detection devices are available.

Specifications

| Attribute | Details |

|---|---|

| Type | Air Cushion Belt Conveyor |

| Applications | Food Industry, Grain Terminals, Mining, Coal, Chemical Industry, Steel |

| Design | Fully-enclosed, Low Noise, Environment-friendly |

| Chamber Options | Single Chamber, Double Chamber |

| Features | Self-cleaning feed recycle device, Inspection door, Observation window, Dust-collection exhaust inlet |

| Optional Features | Speed detection, Misalignment detection, Anti-blockage detection, Scram detection |

Additional Information

For optimal performance and safety, regular maintenance and monitoring of the conveyor system are recommended. Ensure all optional safety features are integrated based on operational requirements.