Description

The AIR DRIVEN GAS BOOSTER is a cutting-edge pneumatic solution designed for the compression of a wide variety of gases, including air, nitrogen, helium, carbon dioxide, neon, argon, oxygen, hydrogen, methane, and natural gas. This versatile booster is engineered to handle industrial gases with impressive efficiency, achieving operating pressures of up to 25,000 psig (1724 bar) for argon, helium, and nitrogen, 5,000 psig (345 bar) for oxygen, and 15,000 psig (1034 bar) for hydrogen.

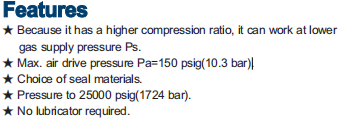

Available in single, double acting, and two-stage models, this compact and robust device ensures reliability and ease of maintenance. Its safety features eliminate the risk of heat, flame, or spark, making it suitable for use in explosion-proof areas. With infinitely variable cycling speeds and outputs, the AIR DRIVEN GAS BOOSTER is an efficient alternative to electrically driven products, providing seamless automatic controls and accommodating continuous stop/start applications without adverse effects.

The innovative design includes a separation between air and gas sections, built-in cooling, and a long-lasting seal system. Notably, it does not require airline lubrication, preserving the purity of the gas and enhancing gas utilization even at extremely low pressures.

Specifications

| Feature | Details |

|---|---|

| Gas Compatibility | Air, N2, He, CO2, Ne, Ar, O2, H2, CH4, Natural Gas |

| Maximum Operating Pressure (Argon, Helium, Nitrogen) | 25,000 psig (1724 bar) |

| Maximum Operating Pressure (Oxygen) | 5,000 psig (345 bar) |

| Maximum Operating Pressure (Hydrogen) | 15,000 psig (1034 bar) |

| Models Available | Single, Double Acting, Two-Stage |

| Safety Features | No heat, flame, or spark risk; ATEX approved, CE certified |

| Lubrication | No airline lubricator required; gas section remains unpolluted |

Additional Information

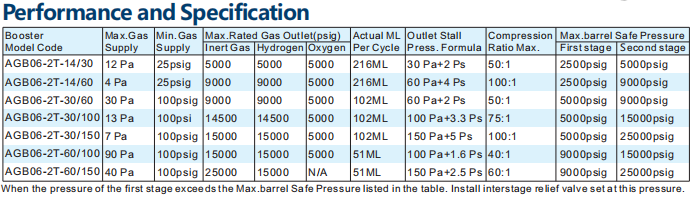

The AGB06 Series is specifically designed with a double drive double stage mechanism, enabling it to stall at any predetermined pressure and maintain that pressure without consuming power or generating heat. This feature significantly enhances operational efficiency and reduces energy waste.