Description

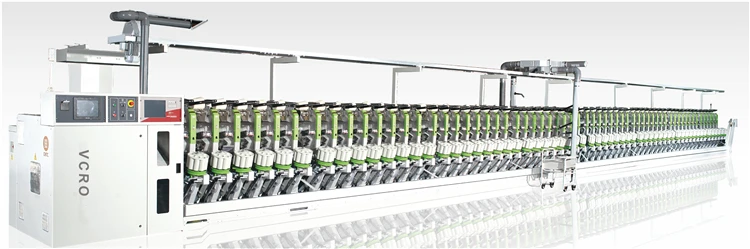

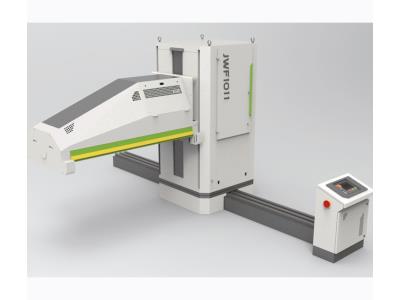

The VCRO automatic winder is a cutting-edge machine that merges the innovative features of the SMARO-NEW series with a stunning new design. This advanced winder is engineered to enhance performance and reliability, featuring an intelligent anti-pattering device and a sophisticated tension control system. With its unique balloon control mechanism, the VCRO ensures flawless package building and consistent winding tension, meeting the high demands of modern manufacturing.

This winder offers a range of improvements that make it stand out:

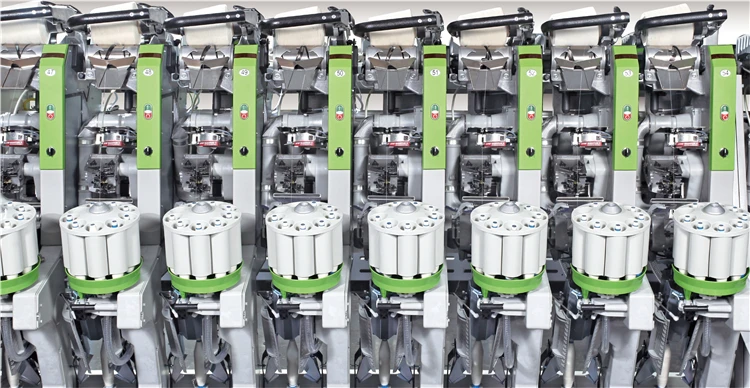

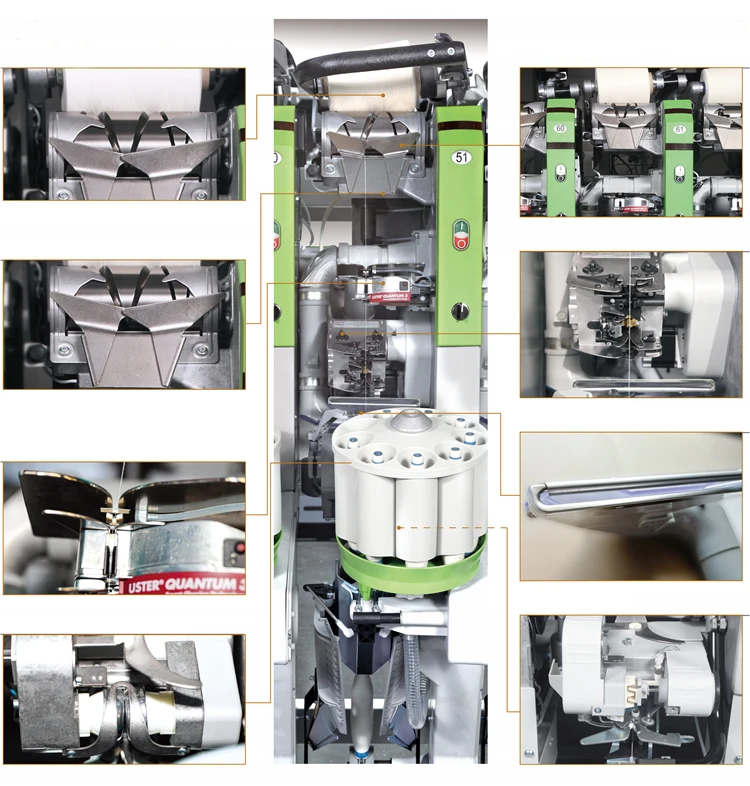

- New Anti-Pattering Mechanism: Prevents the formation of critical patterned yarns during production.

- Advanced Drum Cover: Efficiently keeps the package yarn tail secured, reducing yarn wrap issues.

- Soft Tension Structure: Stabilizes yarn tension, enhancing overall production efficiency.

- Optimized Yarn Control Systems: Includes a close-loop control mechanism and improved suction programs for enhanced reliability.

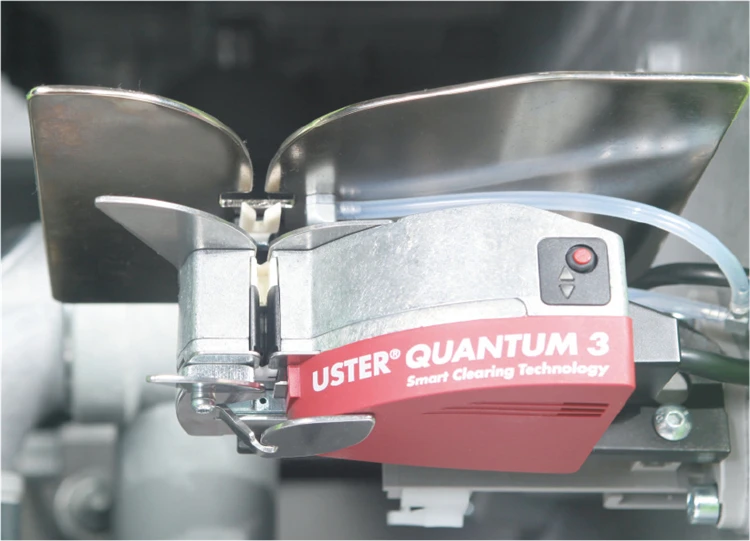

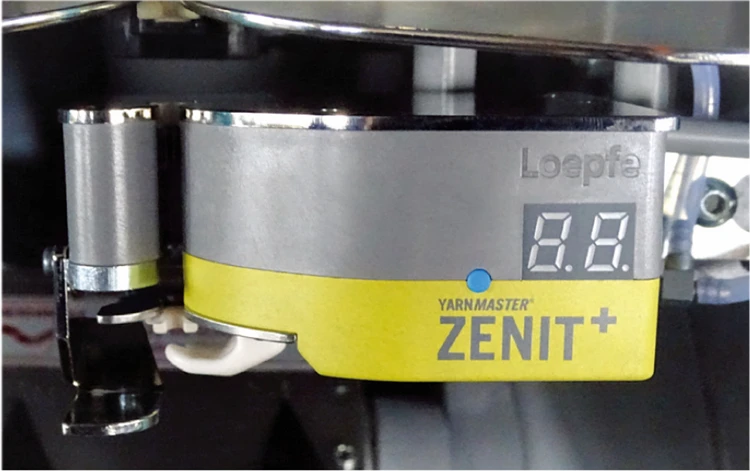

- Top-Level Electronic Yarn Clearer: Monitors yarn quality throughout the winding process, ensuring optimum results.

Specifications

| Type | Single-spindles, single-sided arrangement, left or right hand |

|---|---|

| Winding Speed | 400-2200 m/min, step-less speed regulation |

| Number of Winding Spindles | 6 to 80 every two spacing increments |

| Spindle Distance | 320 mm |

| Applicable Bobbin Taper | 4°20′, 5°57′ |

| Feeding Bobbin | Diameter = 32-65 mm, length = 180-300 mm |

| Joint Type | Airspllicer, Aquasplicer |

| Circles on Drum | 2 or 2.5 |

| Magazine Type | 9 or 6 holes |

| Clearer Type | USTER/LOEPFE electronic yarn clearer |

| Drum | DC motor coaxial transmission, step-less speed regulation |

| Anti-Pattering | Motor speed variation controlled throughout the process |

| Power Installed | 33.57 kW (actual consumption 11-15 kW) |

| Overall Dimension (60 spindles) | 22627 × 1365 × 2650 mm |

Additional Information

The VCRO automatic winder not only enhances production speed by 10-20% but also improves operational reliability through optimized designs and advanced technology. Its electronic yarn clearer manages yarn quality throughout the winding process, offering two settings for normal winding and jointing.