Description

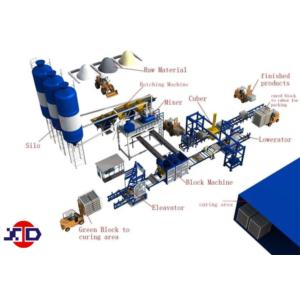

The Hydraulic Automatic Brick Making Machine XD10-15 is designed for efficiency and automation. Utilizing a sophisticated PLC control system, this machine allows production workers to easily set and program operations. It features a seamless integration of electric and hydraulic systems, ensuring a continuous and automated process that includes feeding, distribution, conveyance, die lifting, vibration, and carrying.

This machine is engineered for high yield, making it an ideal investment for large brick factories looking to maximize profit margins. With a robust fault diagnosis system and remote control capabilities, operators can monitor and manage production effectively. The machine’s sturdy construction, including a thick-walled square tube frame and solid steel base, ensures durability and longevity.

Specifications

| Attribute | Specification |

|---|---|

| External Dimension | 3000 x 1980 x 2730 mm |

| Principal Vibration Style | Table vibration |

| Nominal Pressure | 20 Mpa |

| Vibration Frequency | 50~70 HZ |

| Shape Period | 15~20 sec |

| Pallet Size | 1100 x 880 mm |

| Gross Power | 35 KW |

| Overall Weight | 10,500 Kg |

Additional Information

- Components include: belt conveyor, host machine, pallets feeder, green block conveyor, PLC control unit, hydraulic unit, mould, and stacker.

- Advantages: Reliable vibration system, durable construction, and intelligent PLC control for monitoring production metrics.

- Production Capacity:

Name Size PCS/Mould PCS/Hour PCS/8Hours Hollow Block 390×190×190MM 10 2,400 19,200 Solid Brick 240×115×53MM 51 12,240 97,920 Holland Brick 200×100×60MM 35 6,300 50,400 Porous Block 240×115×90MM 24 5,760 46,080 Paving Block 225×112.5×60MM 24 4,320 34,562