Description

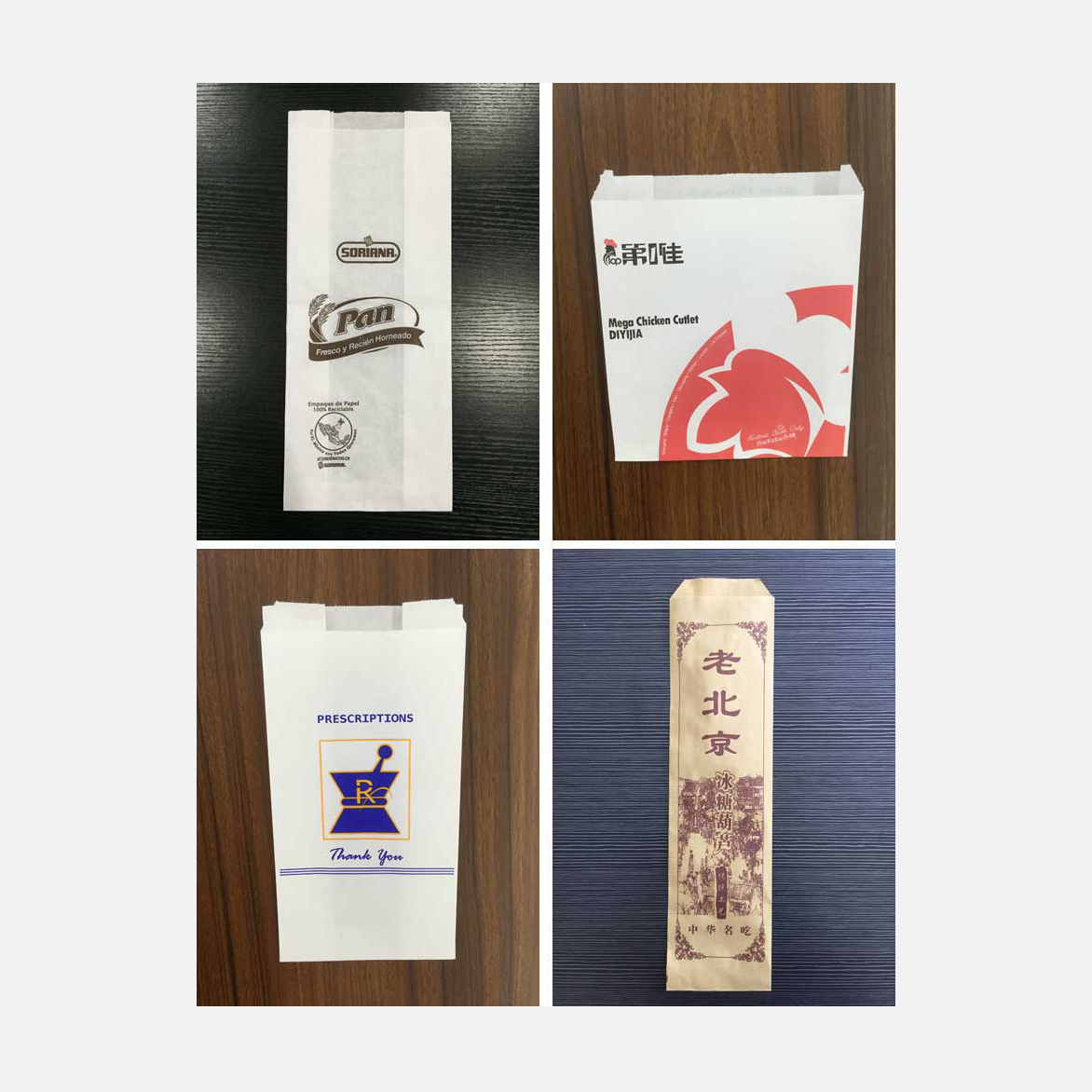

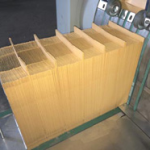

The Automatic High Speed V-bottom Paper Bag Making Machine is a state-of-the-art solution designed for efficient production of paper bags from roll paper. This machine streamlines the entire bag-making process, encompassing edge folding, tube forming, cutting, gluing, bottom folding, bottom gluing, and finishing in a single operation. With its user-friendly design, low power consumption, and high efficiency, it is perfect for manufacturing various types of food bags, including those for bread.

Features

- Touch screen and PC control system for real-time work condition monitoring.

- Accurate servo motor drive for steady and efficient operation.

- Pneumatic lift structure for material lifting.

- Automatic constant tension control for consistent performance.

- Double photoelectric sensor limit for automatic correction and deviation rectification stability.

- Energy-saving design with a long operational life.

- Automatic counting system with user-set counting capabilities.

- Accurate color tracking system that shuts down for color errors.

Specifications

| Attribute | Details |

|---|---|

| Machine Type | Automatic High Speed V-bottom Paper Bag Making Machine |

| Production Process | Roll paper forming, edge folding, tube forming, cutting, gluing, bottom folding, bottom gluing, finishing |

| Control System | Touch Screen and PC |

| Drive Type | Accurate Servo Motor |

| Tension Control | Automatic Constant Tension Control |

| Correction System | Double Photoelectric Sensor Limit |

| Counting System | Automatic with user-set counts |

| Color Tracking System | Automatic shutdown for color errors |

Additional Information

It is recommended to regularly check the calibration of the sensors and maintain the servo motor for optimal performance. The machine is ideal for manufacturers looking to increase production efficiency while maintaining high quality standards in food bag production.