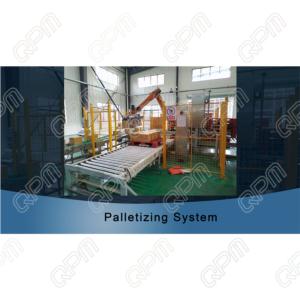

Description

The Automatic Palletizing System is a cutting-edge robotic solution designed to streamline material handling and assembly processes in industrial settings. This innovative system excels in three-dimensional space transfer operations, including grasping, carrying, flipping, docking, and fine-tuning angles. By automating the loading and unloading of materials and the assembly of production parts, it significantly enhances operational efficiency.

With a robust structure, low noise levels, and an extended maintenance interval, the system ensures long service life and minimal downtime. Its short working cycle and reliable operation contribute to improved production efficiency, while adjustable process speeds and positioning capabilities allow for optimal manufacturing accuracy and reduced defective rates. The compact design and large working range enable high-performance operation even in harsh conditions. Additionally, the palletizing robot features optimized gripper designs, accommodating various boxes and different palletizing types through an integrated control system that simplifies program selection.

Specifications

| Feature | Description |

|---|---|

| Palletizing Capabilities | Three-dimensional space transfer operations (grasping, carrying, flipping, docking, fine-tuning) |

| Structure | Sturdy, low noise, long maintenance interval |

| Operational Efficiency | Short working cycle, reliable operation |

| Adjustability | Process speed and positioning can be adjusted |

| Working Range | Large working range with long reaching distance |

| Gripper Design | Optimized designs with the ability to apply different grippers |

| Control System | Integrated programs for different palletizing types |

Additional Information

- Long uptime and low maintenance cost.

- The system is designed to perform efficiently even under harsh operational conditions.