Description

The Automatic Sauce Multi-line Packing Machine is a state-of-the-art packaging solution designed for high efficiency and versatility. Ideal for filling various viscous products such as ketchup, mayonnaise, and syrups, this machine features a full line with 12 lanes, ensuring low maintenance and high operational speed. Powered by Panasonic servo motors and PLCs, it promises fast and easy operation, while the automatic packaging material tracking deviation correction device minimizes film waste.

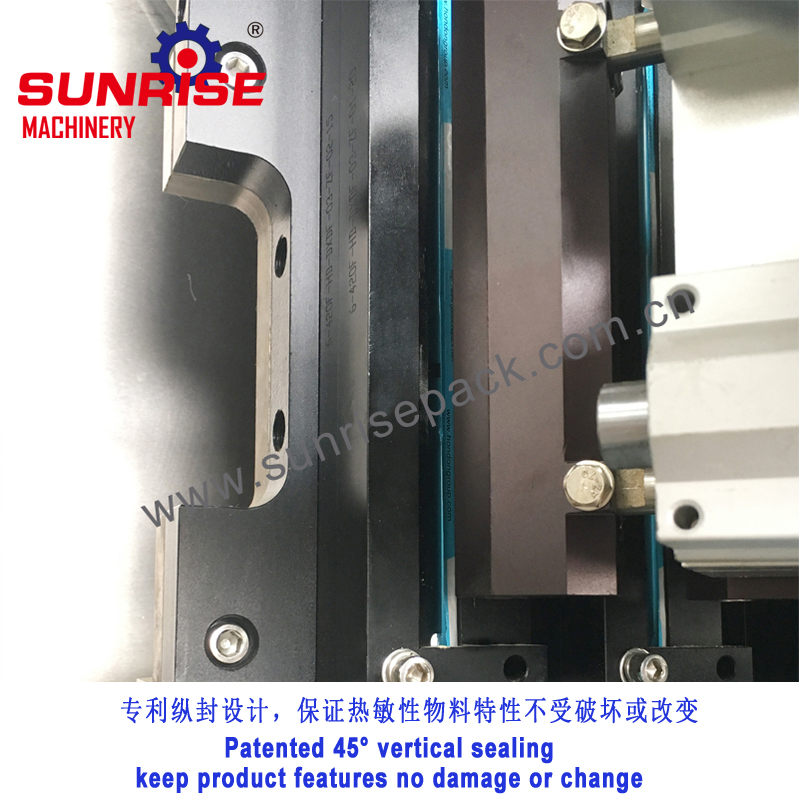

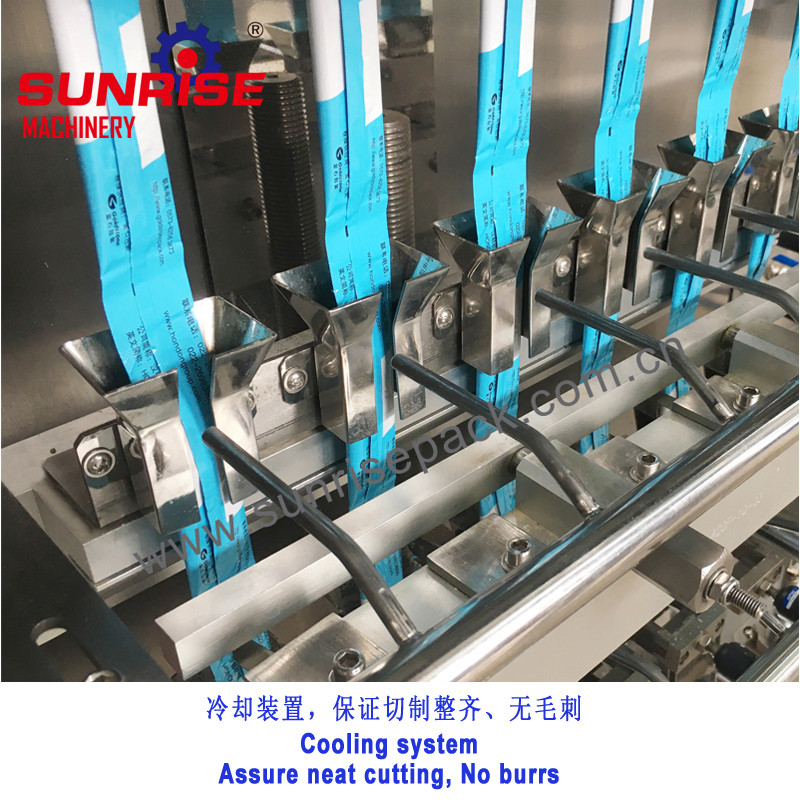

This innovative machine boasts a patented front/back sealing mould lock design that prevents filling deviations, producing neat and visually appealing bags. The movable horizontal sealing design, combined with patented balance techniques, ensures tight and neat sachets. Additionally, its three-dimensional easy tear design guarantees user convenience. With the capability to maintain filling temperatures of liquids up to 90℃, it is suitable for hot filling products.

Extra features include a unique filling suction device that eliminates leakage, ensuring tight and neat bags, and an advanced filling method specifically designed for sticky materials. This machine also incorporates a mixer inside the hopper to prevent sedimentation, ensuring even and smooth filling. Furthermore, an anti-static device keeps the packing film surfaces clean, and a packing film joint detector can save on both product and labor costs. With tele-assistance available, service time and costs are significantly reduced.

Specifications

| Attribute | Specification |

|---|---|

| Maximum Width of Film | 900mm |

| Maximum Number of Lines | 12 lines |

| Capacity | 30-60 bags/min/line |

| Maximum Filling Range | 40ml |

| Power | 380V, 50HZ, 5KW |

| Air Consumption | 0.5 L/Min |

| Weight of Machine | 1500kg |

| Dimension | 1800*2000*2900mm (L*W*H) |

| Packaging Material | Heat-sealable lamination |

Additional Information

- Equipped with an optional double jacket hopper and mixer for maintaining optimal filling temperature.

- Independent research and development designed special filling method for sticky materials, ensuring clean sealing margins.

- Tele-assistance available for timely support to reduce service time and costs.