Description

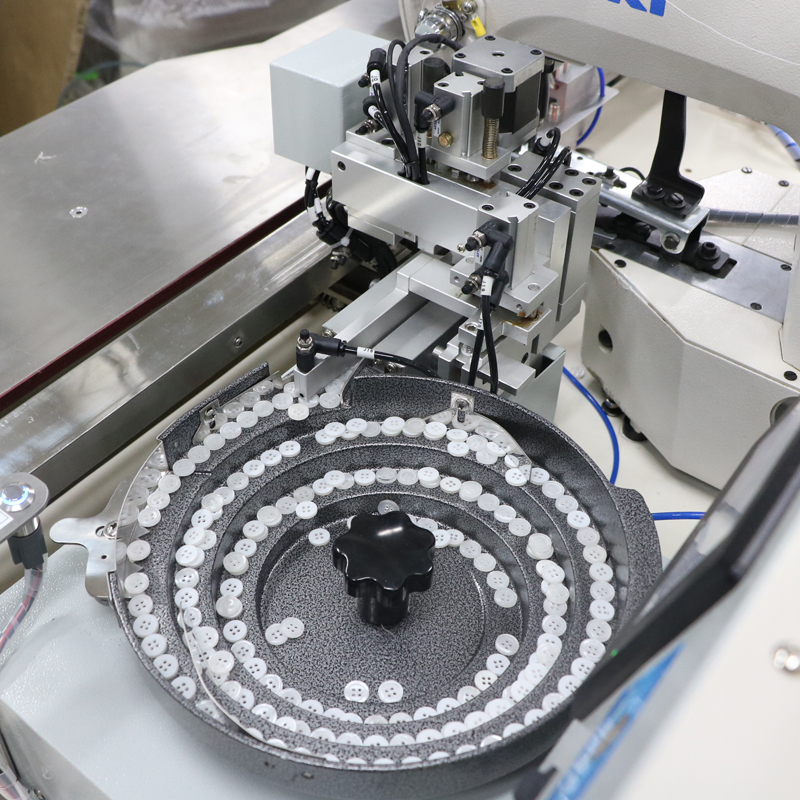

The Automatic Shirt Button Sewing Indexer is an innovative solution designed to enhance efficiency in the garment manufacturing process. This advanced machine is tailored for automatic button sewing on the under placket of both men’s and women’s shirts, making it an essential tool for modern clothing production. It supports both 2-hole and 4-hole button sewing with a manual adjustment feature that allows users to set the distance between fabric clips, ensuring versatility and precision.

One of the standout features is the ability to manually adjust the distance from the button to the under placket edge, accommodating various placket widths for different shirt designs. With a highly accurate button feeding device and an automatic fabric feeding system, this indexer significantly boosts production efficiency, allowing a single worker to operate two machines simultaneously, achieving an impressive output of 3,300 to 3,600 pieces in an 8-hour shift.

Additionally, it includes a left-side automatic workpiece collecting device, enhancing workflow and organization. The machine’s adjustable button sewing range and center distance provide further customization options to suit specific sewing requirements.

Specifications

| Feature | Details |

|---|---|

| Suitable for | Automatic button sewing on under placket of shirts |

| Button types supported | 2-hole and 4-hole buttons |

| Manual adjustment range | Button sewing range: 320~620 mm, Button center to placket edge: 5~19 mm |

| Output | 3,300~3,600 pcs/8 hours (6 buttons/piece) |

| Sewing head | JUKI LK-1903BNSS301/MC672KNN |

| Button feeding claws | 6 pieces of 4-hole claws (various sizes) and 6 pieces of 2-hole claws (various sizes) |

Additional Information

For optimal performance, ensure regular maintenance of the sewing head and feeding devices. Adjust settings according to the fabric type and button specifications for best results.