Description

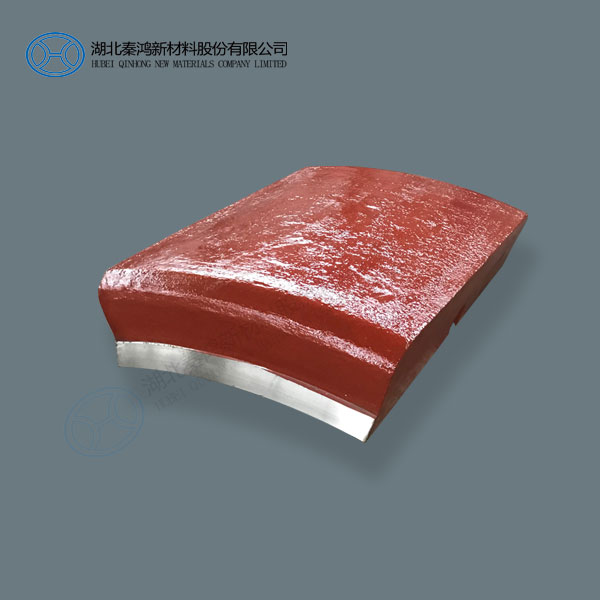

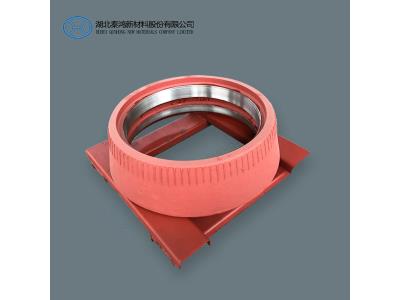

The AUTOX OK series metal matrix ceramic composite roller segment is an innovative solution designed for enhanced wear resistance in industrial applications. Manufactured in accordance with production standards EN 12513, ASTM A532, and GB/T8263, this roller segment features a unique blend of Cr18-28% alloys combined with refractory oxides and compounds, ensuring durability and longevity. With a hardness of 60±2 HRC, it stands out for its exceptional performance in demanding environments.

Our company has pioneered the research and development of composite cermet wear-resistant roller sleeves and lining boards, which are protected by independent intellectual property rights. The ceramic wear-resisting layer is strategically designed to extend the service life of wear parts significantly, outperforming traditional materials.

The roller segment’s surface features a special pit structure that minimizes relative sliding between the working face and materials, resulting in increased vertical mill output by approximately 5%. This innovative design not only enhances wear resistance but also reduces ventilation resistance and vibration, ultimately leading to lower operational costs.

Specifications

| Attribute | Details |

|---|---|

| Production Standards | EN 12513, ASTM A532, GB/T8263 |

| Material Composition | Cr18-28% + Refractory Oxides/Compounds |

| Hardness | 60±2 HRC |

| Service Life | Twice that of traditional materials |

| Grinding Depth | Less than 45mm |

Additional Information

The interior material primarily consists of high chromium cast iron, allowing for repairs through surfacing after wear, thus reducing procurement costs associated with purchasing new rolls. This roller segment is designed to be versatile, enabling use on both sides to further extend its operational life and minimize maintenance requirements.