Description

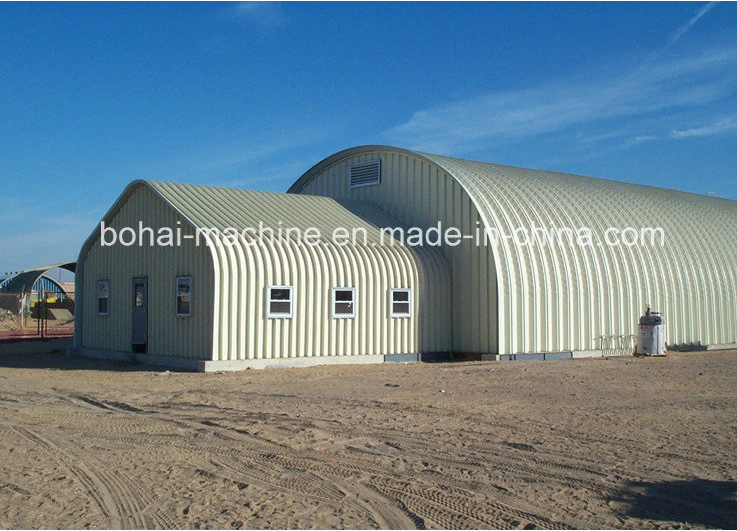

The Bh Automatic Roll Forming Machine is engineered for versatility and efficiency, designed to create a multitude of shapes with precision. Its PLC intelligent control system enhances automation, significantly improving production efficiency while minimizing raw material costs. This machine is ideal for various applications and is built to last, thanks to its robust construction and strict quality control standards. Installation is straightforward, allowing users to maximize their workspace effectively. Renowned for its exceptional quality and reasonable pricing, the Bh Roll Forming Machine is trusted by numerous large companies worldwide for repeated orders.

Key Features:

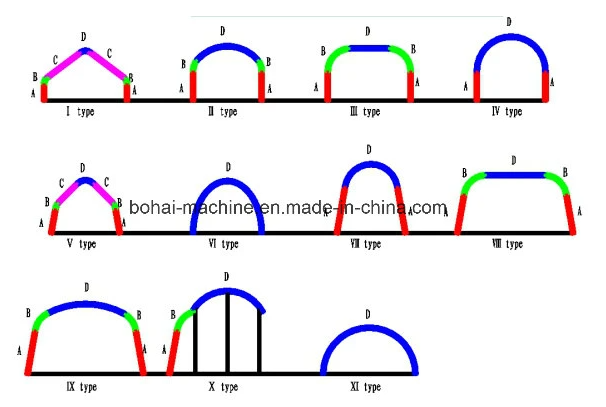

- Ability to produce diverse shapes with high precision.

- Highly automated operation for increased efficiency.

- Cost-effective by reducing raw material waste.

- Simple installation process.

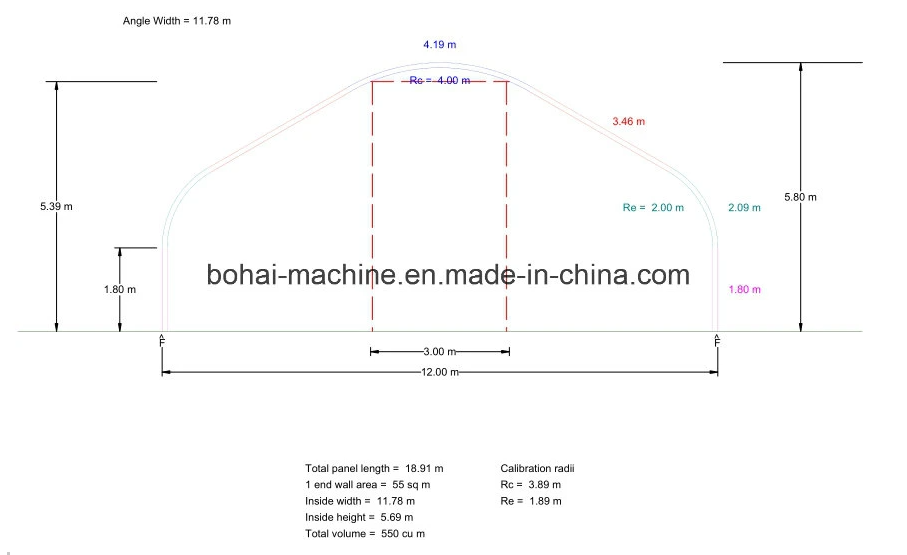

- Maximized use of inner space.

- Widespread applicability in building construction.

Specifications

| Specification | Details |

|---|---|

| Size | 11000mm x 2200mm x 2100mm (with double axles, 8 tires) |

| Total Weight | About 10 Ton |

| Thickness of Bending Leaf | 10mm |

| Cutting Material | 12CrMoV, Heat treatment |

| Cutting Type | Mechanical Cutting Device |

| Forming Type | Roll-formed and length-set cutting |

| Total Motor Power | 23.45KW |

| Main Motor Power | 5.5KW |

| Bending Power | 3.0KW + 1.5KW |

| Cutting Power | 3.0KW |

| Hydraulic Station Power | 7.5KW |

| Servo Power | 0.75KW |

| Seaming Power | 1.1KW + 1.1KW |

| Material of Rollers | 45# steel, quenched HRC 55~65, plated with hard chrome |

| Material of Shafts | 45# steel, galvanized |

| Bearing | Made in Harbin |

| Step of Molding | 13 + 1 |

| Width of Steel Sheet | Feeding Width: 600mm, Finished Width: 305mm, Utilization Ratio: 50.8% |

| Rolling Thickness | 0.6-1.5mm |

| Applicable Span | 4~28m |

| Working Speed | Straight Sheet: 15m/min, Arch Sheet: 13m/min, Seaming: 16m/min |

| Uncoiler | Coil Inner-diameter: 450mm ~ 650mm, Fixed Coil Max Width: 600~620mm |

| Load | 10 Ton |

Additional Information

This machine is backed by our dedicated professional engineering team, offering design support tailored to customer needs and overseas technical guidance services. Our factory takes pride in producing its own machine accessories, reducing costs while ensuring compliance with safety export standards.