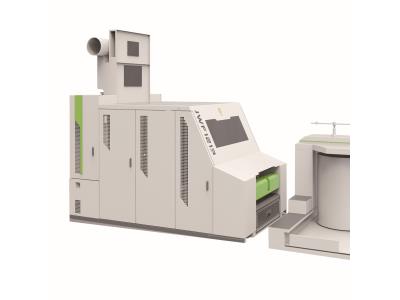

Description

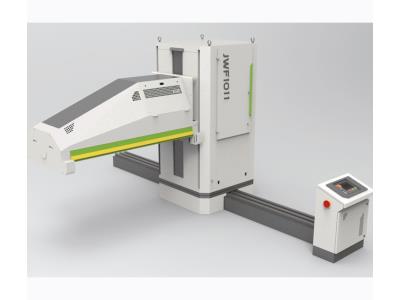

The JWF1011 Textile Machinery Blowing Room Fiber Bale Plucker is an advanced solution for cotton processing, designed to enhance productivity and efficiency in textile manufacturing. This machine is characterized by its flexible action, reliable precision, and high levels of automation and intellectualization. Building on the mature technology of its predecessor, the JWF 1009, the JWF1011 has been optimized in key components such as the plucking arm, suction chamber, beater, grid, cotton compressing roller, and suction slot to achieve an impressive production capacity of 2000 kg/h.

Main Features:

- Increased teeth on the beater blade for fine plucking.

- Double-motor drive for the beater, ensuring optimal production efficiency.

- Enlarged beater center distance to minimize air current interaction, allowing for smooth cotton tuft transfer.

- Innovative cotton compressing roller design for effective tuft plucking.

- Optimized suction chamber profile for improved air suction volume and tuft transfer efficiency.

- Expanded suction slot area for high production transportation of cotton.

- Flexible action and precise control for seamless integration with blowroom and card systems.

- Adjustable grid height to accommodate various production requirements.

- Technologically equipped to handle multiple materials with one machine.

Specifications

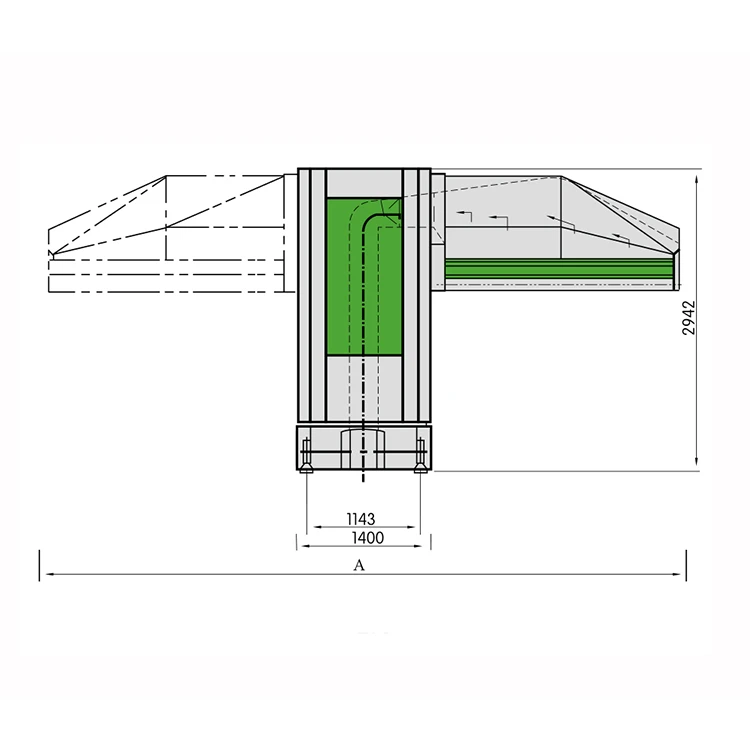

| Attribute | Value |

|---|---|

| Working width (mm) | 2300 |

| Production (kg/h) | 2000 |

| Blade number (PSC) | 22 |

| A (mm) | 6558 |

| Material suited | Pure cotton or chemical fiber below 76 mm |

| Plucking width (mm) | 2300 |

| The maximum bale height (m) | 1.6 |

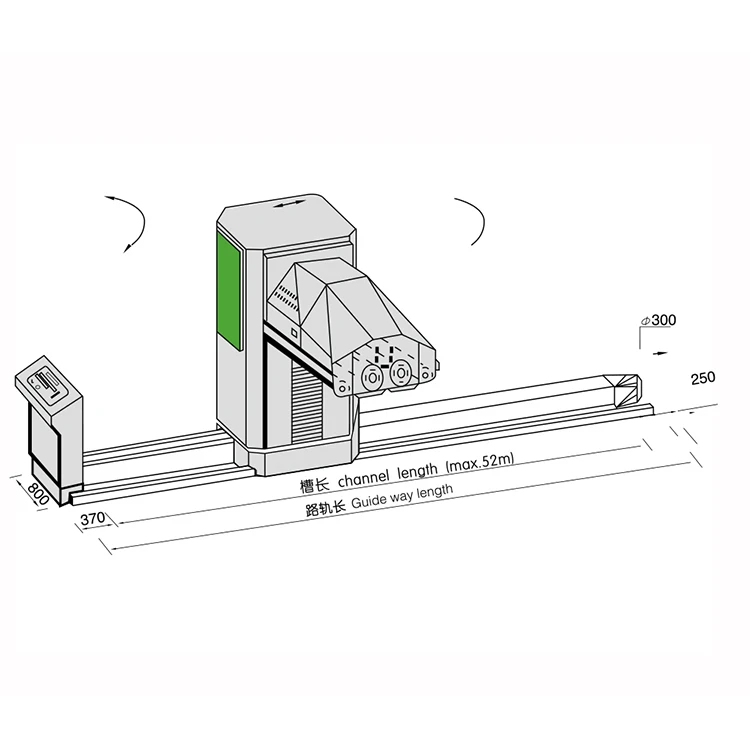

| Suction slot length (m) | 16~50 |

| Beater speed (r/min) | Speed control by inverter |

| Beater descending speed (mm) | 0.1~20 |

| Total power installed (kW) | 11.92 |

| Beater driven power (kW) | 8 |

Additional Information

No additional information is available.