Description

The Bottle Blowing Machine is designed for high efficiency and precision in producing bottles. Featuring a user-friendly man-machine interface, this advanced machine automates the entire bottle blowing process. It integrates automatic billet feeding, bottle blowing, and includes a magnetic induction switch for enhanced operational safety. Equipped with a PLC control system, it ensures that each cylinder undergoes thorough testing and operates within designated parameters. If any component fails to reach its required position, the machine automatically halts to prevent further actions, providing a reliable and safe working environment.

This machine is fast, accurate, and stable, making it an excellent choice for production lines. The cross hyperbolic arm applies a strong clamping force to pressurize and lock the mold, allowing for adjustable die stroke based on product size, which reduces the opening and closing time. Its far-infrared heating tube ensures a strong, uniform preform rotation heating, with separate PLC or electronic voltage regulation for each heating group.

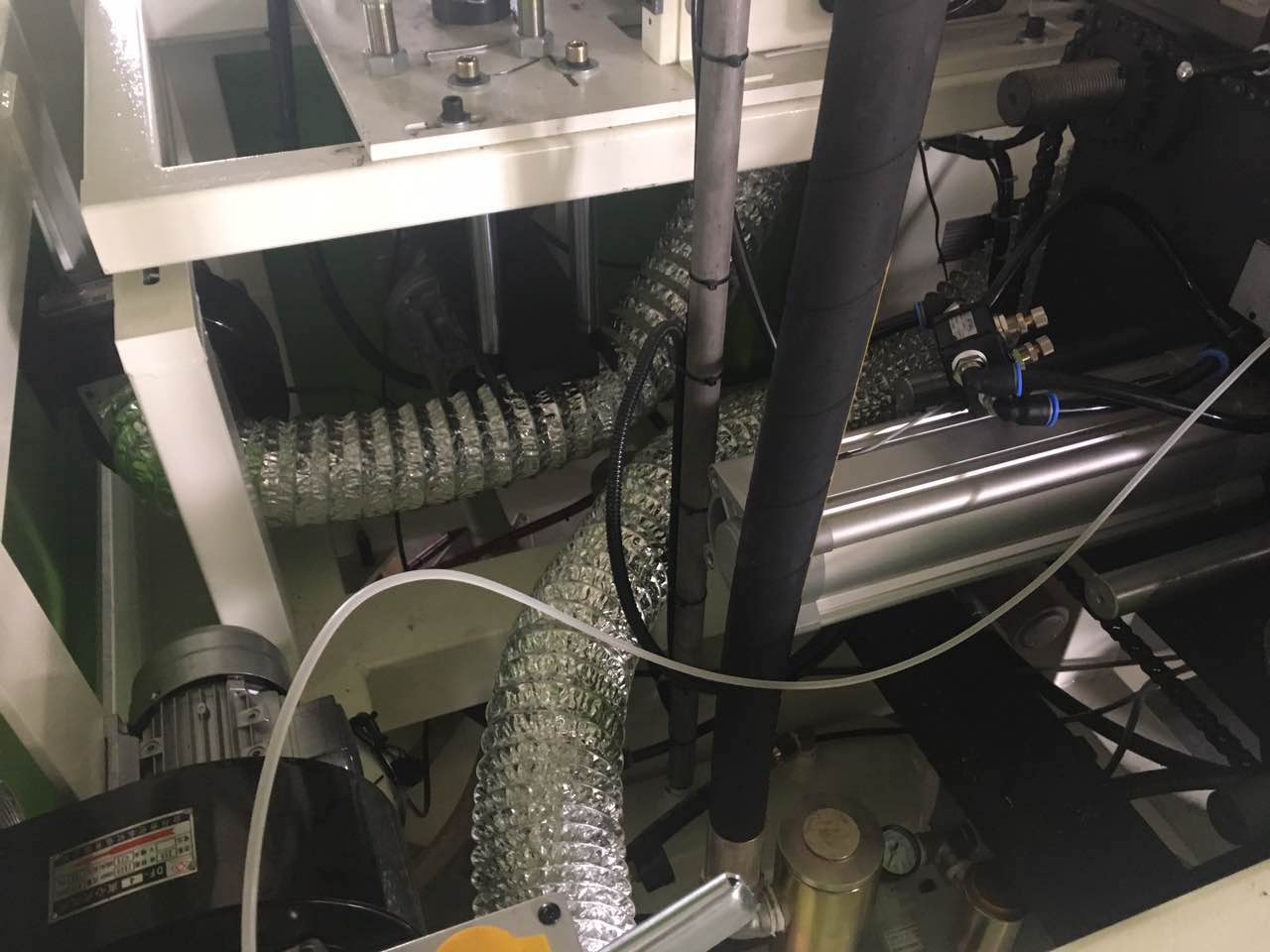

Featuring a unique oven design, the bottle heating process is optimized for energy efficiency. It allows for close spacing of heating bottles, thus shortening drying channels and reducing overall energy consumption. The air circuit is meticulously designed, dividing it into micro blowing, high pressure blowing, and low pressure actions to cater to different air source requirements for various products. Additionally, an automatic oil pumping device is included to enhance machine protection, ensuring a seamless production process.

Specifications

| Feature | Description |

|---|---|

| Control System | Man-machine interface with PLC control |

| Heating Method | Far-infrared heating tube |

| Clamping Mechanism | Cross hyperbolic arm with adjustable die stroke |

| Air Circuit Design | Micro blowing, high pressure blowing, low pressure action |

| Maintenance | Automatic oil pumping device |

| Energy Efficiency | Optimized oven design to reduce energy consumption |

| Production Process | Fully automated with high operational efficiency |

Additional Information

- Automatic production process ensuring good product quality and cleanliness.

- High operational efficiency with easy maintenance.

- Safe operation with simple setup and usage.