Description

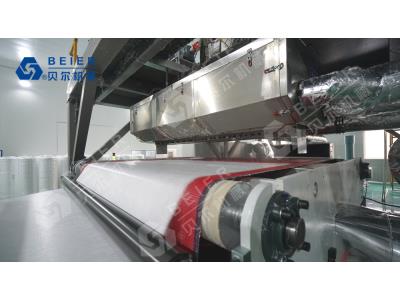

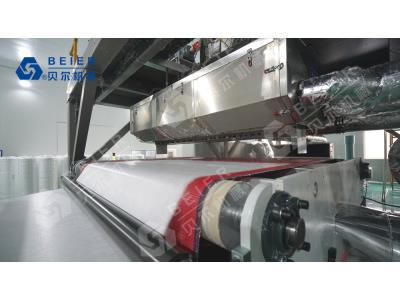

The BR1600 PP Melt-blown Fabric Production Line is a state-of-the-art equipment designed for the production of melt-blown non-woven fabrics using polypropylene as the primary raw material. This advanced line incorporates master batches and additives such as anti-oxidation agents, static electret, and flame retardant materials to create melt-blown fabrics available in various colors and functionalities. The versatility of this production line allows for the manufacturing of products suitable for industrial applications, including industrial felt, oil-absorbing cloth, sound insulation cotton, and high-efficiency filter materials. Additionally, it is capable of producing melt-blown fabric specifically for masks, ensuring high-quality output tailored for various uses.

Process Introduction:

The melt-blown nonwoven process utilizes high-speed hot air to draw a thin stream of polymer melt extruded from the die orifice, forming ultra-fine fibers that condense on a screen or roller. This self-adhesive process results in the creation of non-woven fabric.

Standard Process:

Polymer preparation → Melt extrusion → Metering pump → Melt-blown die head assembly → Melt flow stretching → Cooling → Coiler

Specifications

| Attribute | Details |

|---|---|

| Main Material | Polypropylene |

| Production Capability | Melt-blown non-woven fabrics |

| Applications | Industrial felt, oil-absorbing cloth, sound insulation cotton, high-efficiency filter materials, mask fabric |

Additional Information

No additional information is available at this time.