Description

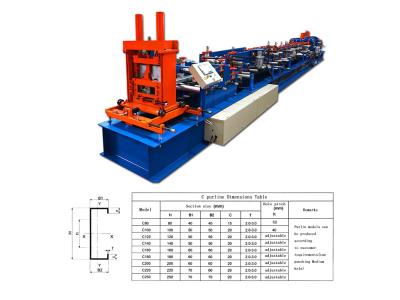

The C Z Purlin Roll Forming Machine is a highly efficient and versatile equipment designed specifically for producing C and Z section purlins. This cold roller machine is engineered for precision and durability, making it an essential tool for construction and manufacturing industries. With advanced features such as a PLC control system and a robust hydraulic motor, this machine guarantees high performance and reliability.

Its configuration includes a manual uncoiler, guiding platform, and a main machine for roll forming, along with pre-punching and pre-cutting devices. The machine operates at a forming speed of 12-24 meters per minute, allowing for efficient production. Designed to handle various thicknesses, it can accommodate feeding thicknesses between 1.5 to 3.0 mm.

Specifications

| Attribute | Details |

|---|---|

| Configuration | Manual Uncoiler, Guiding Platform, 9 Shaft Strip Leveler, Main Machine Of Roll Forming, Hydraulic Motor, Pre-Punching Device, Pre-Cutting Device, Hydraulic Station, PLC Control, Supporter Table |

| Control System | PLC Inverter Encoder Touch Screen |

| Main Frame | 400mm H-Beam |

| Total Power | 22 kw |

| Power Supply | 380V, 3-Phase, 50Hz |

| Forming Speed | 12-24 m/min |

| Roll Station | 18 stands |

| Roller Diameter | 80 mm |

| Effective Width | 80-300 mm |

| Feeding Thickness | 1.5-3.0 mm |

| Backboard Thickness | 20 mm |

| Cutter Standard | GCr12 |

| Roller Standard | Gcr15# |

| Overall Size | About 8500×1000×1400 mm |

| Total Weight | About 10T |

| Custom | According to customer’s requirements |

Additional Information

Packing Details: The main machine is nude in the container, while the computer control box is packed with wooden packaging.

Delivery Detail: 20 days