OEM ODM cable tray making machine drywall manufacturing machine roofing sheet making machine

Description

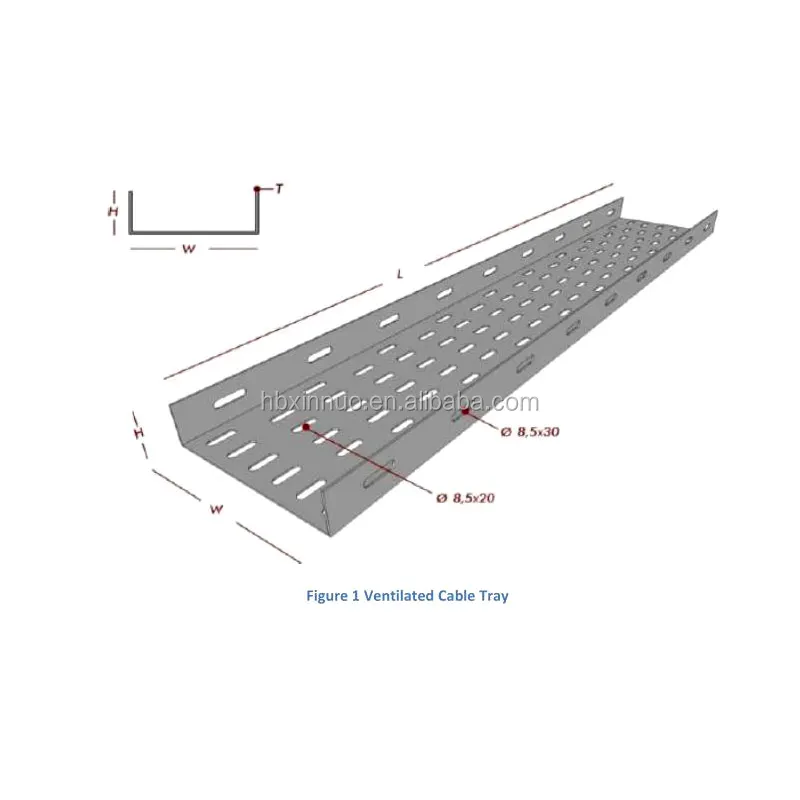

The Cable Tray Making Machine is a highly efficient and economical solution for producing cable trays, drywall, and roofing sheets. Designed with advanced technology, this machine incorporates a manual uncoiler, a robust roll forming system, a computer control system, a hydraulic control system, and a cutting mechanism, all seamlessly integrated to enhance production efficiency. With its capability to process color steel plates, this machine meets the demands of modern manufacturing, ensuring high-quality output.

Specifications

| No. | Specification | Details |

|---|---|---|

| 1 | Suitable to process | Color steel plate |

| 2 | Width of the plate | 300-900mm |

| 3 | Rollers | 18-22 rows |

| 4 | Dimensions | 10.5 x 1.6 x 1.5 m |

| 5 | Power | 11 + 4 kW |

| 6 | Thickness of the plate | 0.5-1.2 mm |

| 7 | Productivity | 4-6 m/min |

| 8 | Diameter of the roller | 90 mm |

| 9 | Weight | About 8.0 T |

| 10 | Voltage | 380V 50Hz 3 phases |

| 11 | Rolling material | Carbon Steel 45# |

| 12 | Material of the cutting plate | Cr12 |

| 13 | Processing precision | Within 1.00 mm |

| 14 | Control system | PLC control |

Product Pictures

Related Products

Product Inquiry Form

Thanks your message successfully submitted.