Description

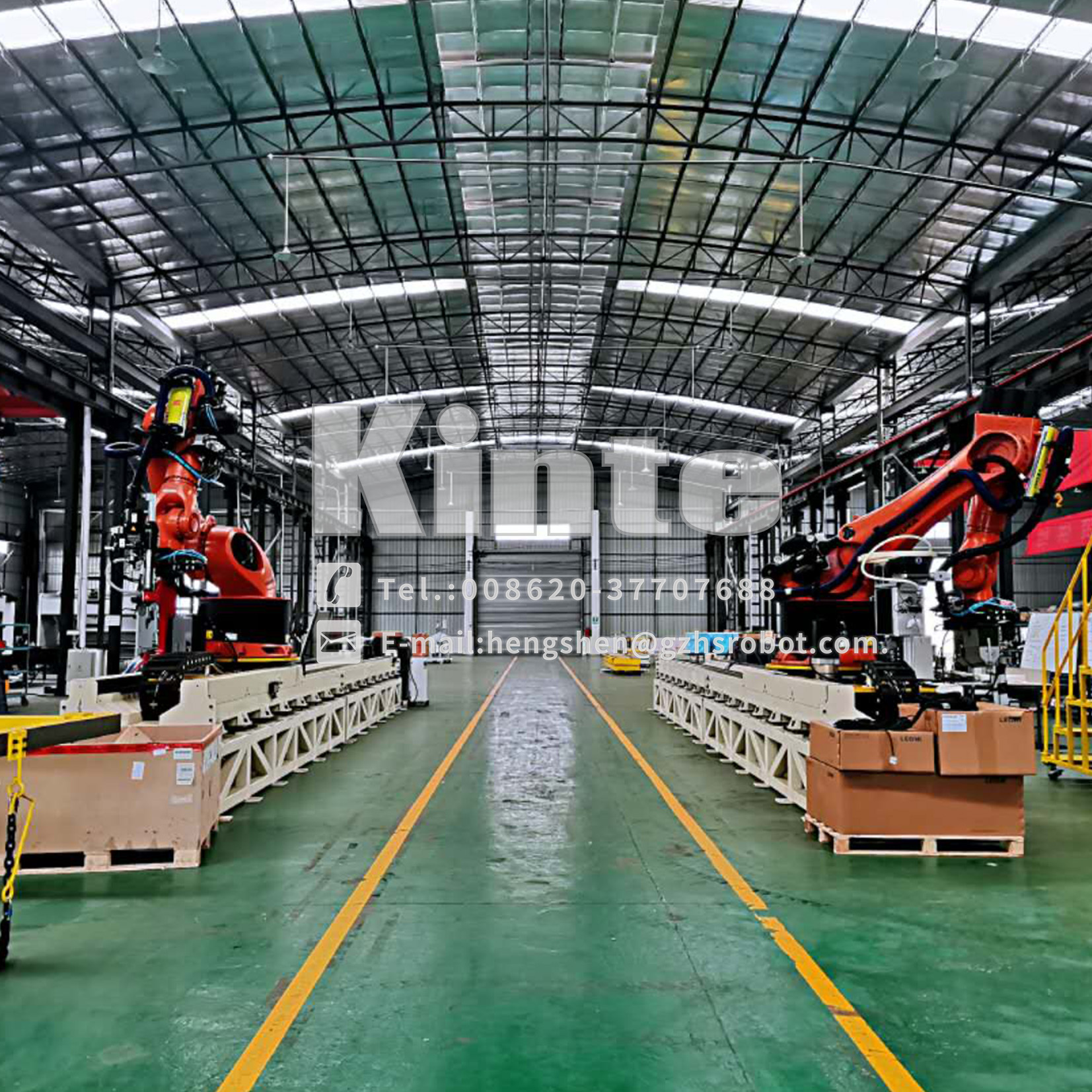

The Car Aluminum Body Production Line is a state-of-the-art manufacturing solution designed for the automotive industry. Developed by Kinte Automotive Engineering Research Institute, this innovative production line incorporates advanced technology in welding, assembly, and inspection processes. With a commitment to integrity, technological innovation, and quality, this line aims to meet the high standards of modern automobile manufacturing.

Equipped with a Siemens PLC system and utilizing FANUC robots, this production line is capable of handling a diverse range of vehicle models, including Class A, Class B, SUVs, and MPVs. The line is designed for efficiency and precision, featuring essential equipment such as rolling machines, sliding concrete, rotating roller beds, and assembly fixtures. It is particularly known for its robust welding capabilities, including laser welding and connections for lightweight materials.

Specifications

| Attribute | Details |

|---|---|

| Project Name | GAC Car Aluminum Body Line Project |

| PLC System | Siemens |

| Robot Brand | FANUC |

| Model | Full platform models (Class A, Class B, Class C, SUV, MPV) |

| Main Equipment | Rolling machine, sliding concrete, rotating roller bed, total assembly fixture, robot, FDS, SPR |

Additional Information

The Kinte Automotive Engineering Research Institute specializes in various engineering aspects of automobile production, including factory design, stamping, welding, assembly, and inspection. Their strong design and manufacturing teams ensure the successful execution of large-scale projects, making them a leader in innovative automotive manufacturing solutions.