Description

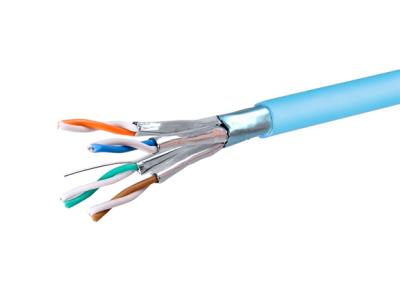

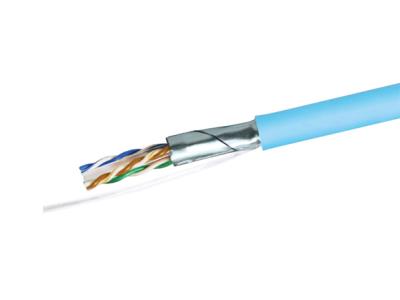

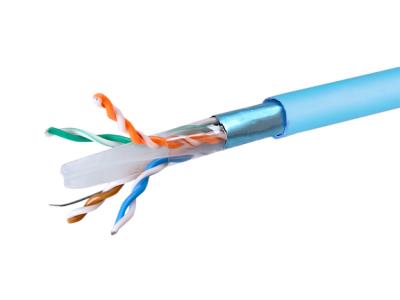

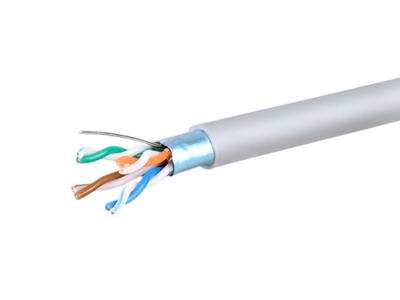

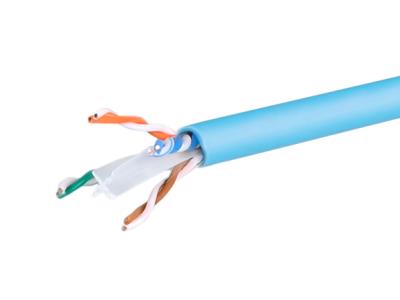

The CAT6A cable is engineered for high-speed data transmission, utilizing premium oxygen-free copper material to deliver exceptional tensile and electrical resistance properties. Its optimized design incorporates advanced high-speed cable pitch technology and a specialized skin foam insulation production process, enhancing transmission performance indicators like crosstalk and return loss. This results in an impressive transmission bandwidth, making it ideal for modern networking needs. Fully compliant with REACH and RoHS regulations, the CAT6A cable is a reliable choice for both residential and commercial applications.

Specifications

| Parameter | Description |

|---|---|

| Conductor | Solid bare copper |

| Insulation Materials | High-density polyethylene (unshielded), skin-foamed skin polyethylene (shielded) |

| Insulation Diameter | 1.10 ± 0.05 mm (unshielded), 1.33 ± 0.05 mm (shielded) |

| Shield | Aluminum foil (shield) |

| Sheath Diameter | 7.1 ± 0.5 mm (unshielded), 7.3 ± 0.5 mm (U/FTP shielded), 7.5 ± 0.5 mm (F/FTP shielded) |

| Sheath Material | PVC or LSZH low smoke halogen-free (according to different jackets) |

| Working Temperature | -30℃ to 50℃ (LSZH), -20℃ to 50℃ (PVC) |

| Tensile Strength Before Aging | ≥13.5 MPa (PVC), ≥10.0 MPa (LSZH low smoke halogen-free) |

| Elongation Before Aging | ≥150% (PVC), ≥125% (LSZH low smoke halogen-free) |

| Transmission Delay Difference | ≤45 ns / 100 m |

| Transmission Speed | 69% (unshielded), 74% (shielded) |

| DC Resistance | Maximum 9.38 Ω / 100 m |

Additional Information

- Reference Standard: UL444, UL1581, UL1666, IEC60332-1, IEC60332-3-24, EN50399

- Test Standard: ISO/IEC11801, ANSI/TIA-568-C.2, IEC-61156-5