Description

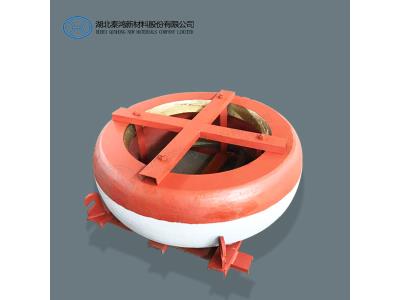

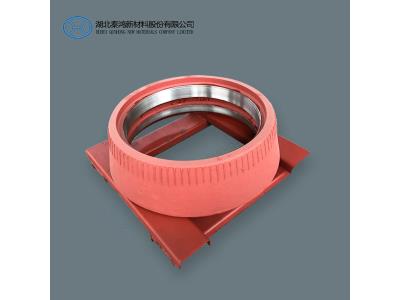

The Cement Plant Raw Mill and Cement Mill MMC Roller Tyre is a cutting-edge wear-resistant component designed specifically for the rigorous demands of cement production. Crafted from a unique metal matrix composite material consisting of Cr18-28% and refractory oxide, this roller tyre boasts a hardness of 60±2 HRC (matrix). It combines the superior wear resistance of ceramic with the plastic toughness of metal, ensuring a long-lasting, reliable performance.

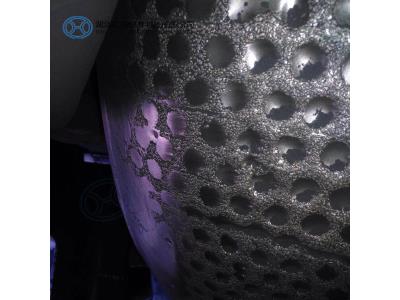

Utilizing a specialized casting and heat treatment process, this product not only extends the service life of castings but also minimizes maintenance and replacement time. With a surface honeycomb structure that reduces relative sliding between work and materials, the roller tyre significantly decreases power consumption, ventilation resistance, and vibration. This innovative design promotes uniform wear, greatly enhancing the longevity of the casting.

Manufactured by Hubei Qinhong, this wear-resistant part outlasts comparable domestic products by 10% and offers superior price performance compared to imported alternatives. It has successfully replaced imported roller segments, liners, and other wear parts across various countries, including Russia, Germany, Pakistan, Costa Rica, Argentina, and Greece.

Our company also provides a diverse selection of imported and domestic roller segments and table segments for vertical mills, compatible with models such as FL Smidth ATOX, Loesche LM, GEBR. PFEIFFER, MPS, RM, CKP, MLS, MPF, TRM, HRM, ZGM, HP, and more.

Specifications

| Standard | ASTM A532, EN 12513, GB/T8263 |

|---|---|

| Material | Cr18-28% + Refractory Oxide |

| Hardness | 60±2 HRC (Matrix) |

| Lifespan | 10% longer than similar domestic products |

| Applications | Vertical mills including FL Smidth ATOX, Loesche LM, GEBR. PFEIFFER, MPS, and more |

Additional Information

This innovative roller tyre is repairable, further reducing procurement costs while enhancing operational efficiency. It is designed for easy integration with existing equipment, making it a valuable investment for any cement production facility.