Description

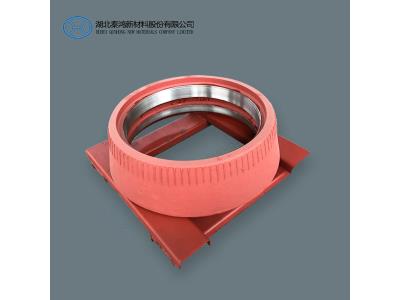

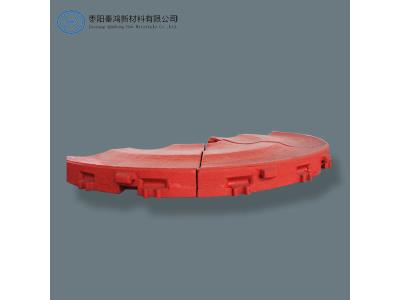

The Cement Plant vertical roller mill wear parts are engineered to enhance the efficiency and longevity of your grinding operations. Manufactured from high-quality materials such as ASTM A532, EN 12513, and GB/T8263, these parts incorporate a high chrome metal matrix ceramic composite, ensuring superior wear resistance. The alloy steel castings provide additional strength, making them ideal for demanding industrial applications.

Advantage: Wear-resistant parts produced by Hubei Qinhong have a lifespan that is 10% longer than similar domestic products, offering better price-performance compared to imported alternatives. These components have successfully replaced imported roller segments, liners, and other wear parts, and are widely exported to countries including Russia, Germany, Pakistan, Costa Rica, Argentina, and Greece.

Corporate Strength: Established in 1993, Hubei Qinhong boasts over 20 years of experience in producing wear-resistant materials. With more than 400 long-term cooperative users across the cement and electric power industries, the company partners with notable manufacturers like Citic Heavy Industries and FL Smidth. Its products are recognized for their quality and are distributed across various regions, including Germany, Denmark, Colombia, and the Far East.

Main Product: The company offers a wide range of imported and domestic roller segments and table segments for vertical mills, including but not limited to FL Smidth ATOX type, Loesche LM type, GEBR. PFEIFFER MPS type, RM type, CKP type, MLS type, MPF type, TRM type, HRM type, and ZGM type. Customization options are also available to meet specific customer requirements.

Specifications

| Material | High chrome metal matrix ceramic composite, Alloy Steel |

|---|---|

| Standards | ASTM A532, EN 12513, GB/T8263 |

| Applications | Cement plants, Electric power industry |

| Customization | Available upon request |

Additional Information

For optimal performance, ensure proper installation and maintenance of the wear parts. Regular inspections are recommended to maximize their lifespan and effectiveness in grinding operations.