Description

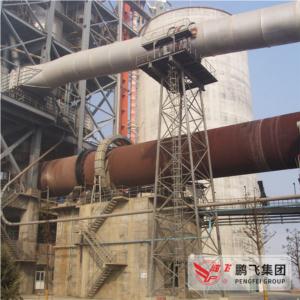

The Chemical Rotary Kiln is an essential industrial apparatus designed for high-temperature processes in various sectors, including building materials, metallurgy, and chemical industries. This robust kiln rotates the barrel via a transmission device, ensuring optimal heat exchange throughout the clinker formation process. Its composition includes refractory bricks, castable materials, and a specialized steel plate cylinder, enabling it to withstand extreme conditions. The kiln’s versatility allows it to handle diverse applications, from calcining cement and active lime to oxidizing roasting of non-ferrous minerals like nickel and chromium. Additionally, it plays a crucial role in environmental protection, aiding in the disposal of solid and hazardous waste.

Main Features: The Chemical Rotary Kiln is designed with various sealing forms, including cylinder compression end face seal, spring compression end face seal, and heavy hammer graphite block seal, among others. This advanced structure ensures strong adaptability to cylinder movement and effective sealing, enhancing operational efficiency.

Application Industries: The kiln is widely used in the chemical industry, specifically for calcium carbonate and titanium dioxide production, magnesium and zinc oxide processing, coal to oil conversion, and oil sand oil shale extraction.

Specifications

| Attribute | Details |

|---|---|

| Material | Refractory brick, castable, steel plate |

| Applications | Building materials, metallurgy, chemical industry, environmental protection |

| Sealing Options | Cylinder compression, spring compression, heavy hammer graphite block, fish scale labyrinth, axial labyrinth, combination seals |

Additional Information

For optimal performance, regular maintenance and inspection of seals and kiln components are recommended. Ensure the kiln is operated within specified temperature ranges to prevent damage and maintain efficiency.