Description

The CNC Drilling and Milling Machine is designed for precision and power, making it an ideal choice for heavy cutting applications. Featuring a sturdy construction with special casting, this machine boasts a high-rigid structure, enhancing durability and performance. It employs a vertical machining center lathe bed and a sliding seat, ensuring exceptional rigidity.

Equipped with a maximum spindle torque of 450NM, this machine is capable of handling demanding tasks with ease. The guide rail and work table undergo quenching and grinding processes, ensuring smooth feeding and high accuracy thanks to the automatic intermittent lubrication system. The three axes are driven by a ball screw, with a direct connection between the motor and screw for reliable operation.

Additionally, the CNC machine can be integrated with the Guangzhou CNC system (model GSK980MDa) to support milling, boring, and drilling cycle processing. User-friendly operation is further enhanced by a 7″ widescreen color LCD display. The spindle box features full gear transmission shifts, increasing the machine’s rigidity and tapping capacity up to M30.

For versatility, the machine can be configured with a 12-position mechanical hand disc knife library or a 16-gear cam manipulator for automatic tool changes during processing, ensuring efficient workflow. The drive devices for the three axes are DA98 series digital servos, while the spindle is powered by the DAY3 series digital spindle servo, both produced by Guangzhou CNC Company.

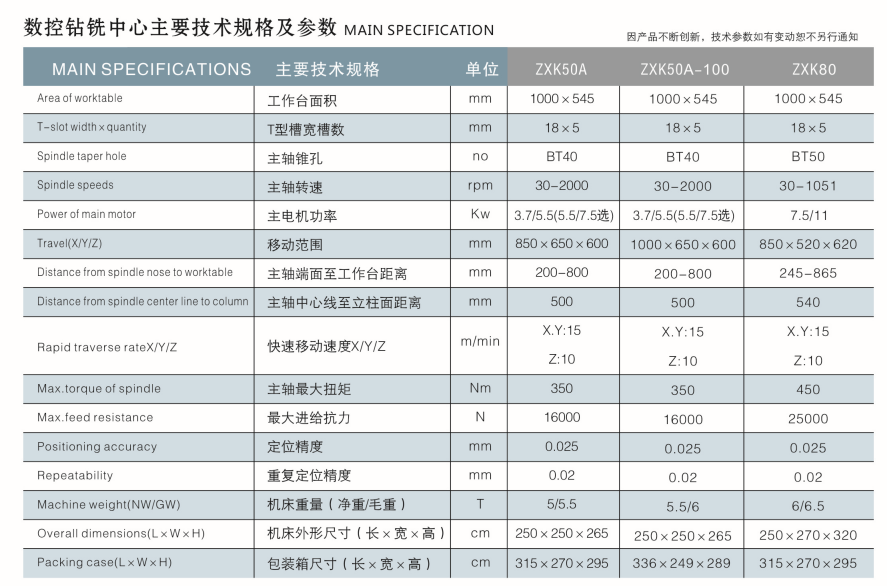

Specifications

| Feature | Details |

|---|---|

| Max Spindle Torque | 450 NM |

| Construction | Special casting with high-rigid structure |

| Drive System | Ball screw drive |

| CNC System | Guangzhou CNC model GSK980MDa |

| Display | 7″ Widescreen Color LCD |

| Tapping Capacity | M30 |

| Tool Library Configuration | 12-position mechanical hand disc or 16-gear cam manipulator |

| Axis Drive Device | DA98 Series Digital Servo |

| Spindle Servo | DAY3 Series Digital Spindle Servo |

Additional Information

- Automatic intermittent lubrication for smooth operation.

- Enhanced rigidity with gear transmission shifts.

- Supports various machining processes including milling, boring, and drilling.