Description

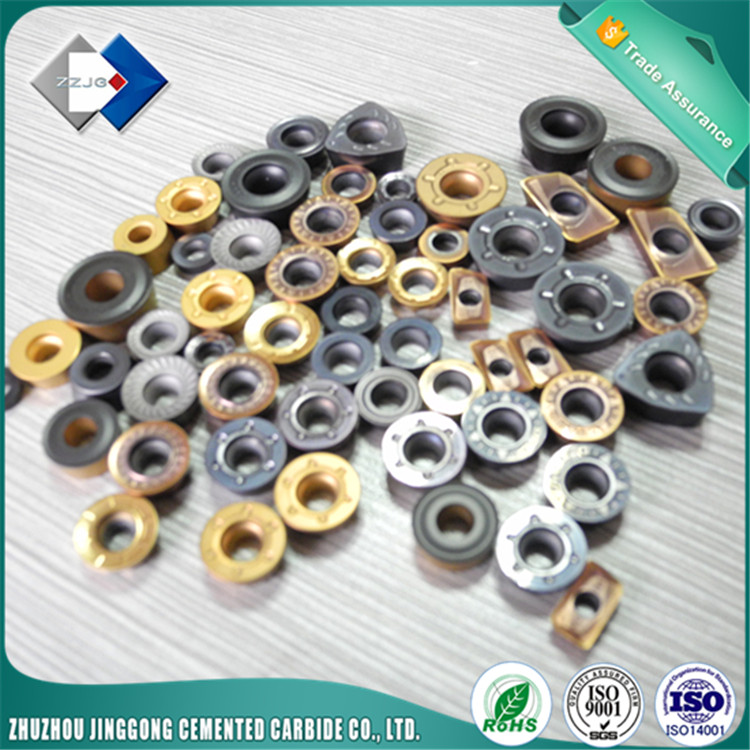

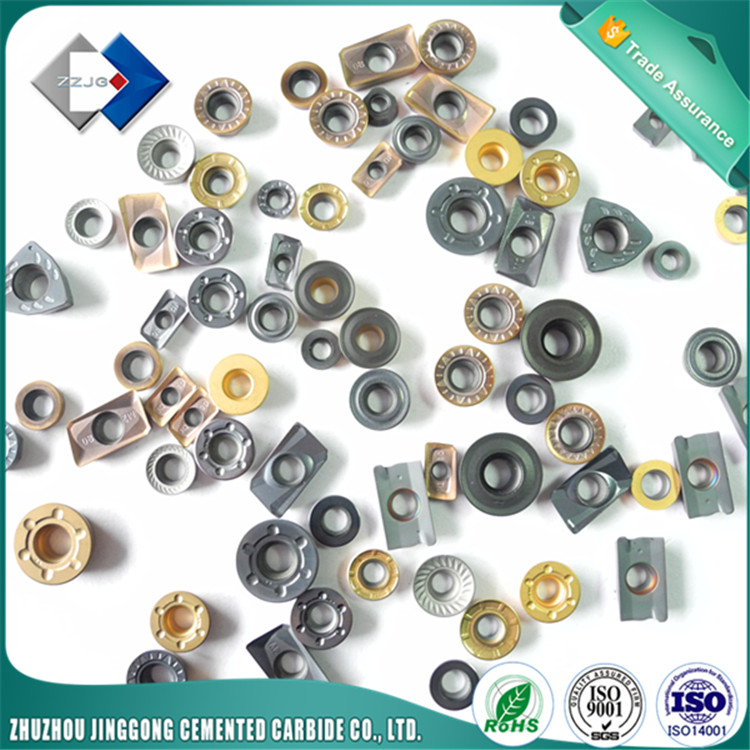

Our CNC Inserts are crafted from 100% virgin tungsten carbide, ensuring exceptional durability and performance across a variety of machining processes. These inserts are expertly manufactured under HIP processing, resulting in outstanding wear resistance and hardness. Ideal for turning, milling, threading, grooving, and cutting tools, they are suitable for materials such as cast iron, steel, copper, and aluminum.

The tungsten carbide cutting inserts come in various shapes and materials tailored to meet specific cutting needs, providing high wear impact resistance. They serve as an excellent alternative to ceramic, coating, and alloy inserts. These inserts are particularly effective for hot process composite materials used in surface refurbishing, offering comprehensive coatings to enhance wear resistance, thermal resistance, corrosion resistance, and impact resistance, along with specialized coatings for sealing, insulation, and super-conduction.

Specifications

| Attribute | Details |

|---|---|

| Material | Tungsten Carbide |

| Manufacturing Process | HIP Processing |

| Durability | High wear resistance and hardness |

| Applications | Turning, Milling, Threading, Grooving, Cutting |

| Suitable Materials | Cast Iron, Steel, Copper, Aluminum |

Additional Information

- Factory Location: Zhuzhou

- Employees: Over 200

- Experience: Over 19 years in the carbide industry

- Output: Over 120 tons per month

- Certifications: RoHS, ISO 9001:2008, ISO 14001:2004

- Quality Control: 100% QC inspection before shipment

- Customization: Non-standard items can be produced according to samples or drawings