Description

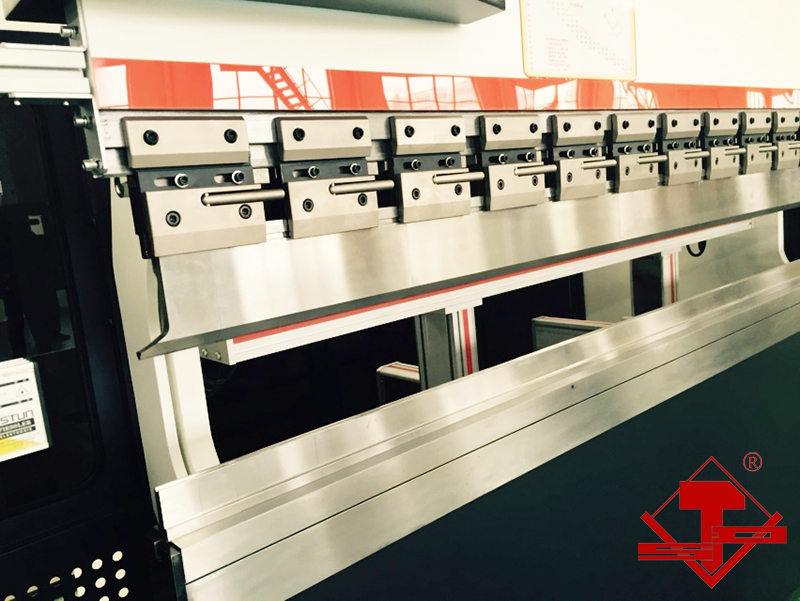

The CNC Press Brake is a state-of-the-art machine designed for precise metal forming and bending. Featuring an up-stroke structure, this machine integrates a hydraulic and CNC control system that enhances operational efficiency. The mechanical and hydraulic systems work seamlessly as one unit, employing an advanced international electric-hydraulic proportion synchronous control system. This ensures that the ram’s speed and position are controlled with unparalleled accuracy, making it ideal for high-precision workpieces.

With its robust design, this CNC Press Brake guarantees stable operation, high repositioning precision, and excellent anti-eccentric loading capabilities. Whether you’re working on complex projects or standard tasks, this machine delivers consistently high-quality results.

Specifications

| Attribute | Specification |

|---|---|

| Model | WE67K-160/3200 |

| Nominal Pressure | 1600 kN |

| Length of Table | 3200 mm |

| Center Distance Between Uprights | 2700 mm |

| Throat | 400 mm |

| Stroke of Ram | 200 mm |

| Max. Open Height | 470 mm |

| Speed | Approaching: 120mm/s; Working: 9mm/s; Returning: 95mm/s |

| Main Motor Power | 11 kW |

| Overall Dimensions (L*W*H) | 3300 x 2210 x 2660 mm |

Additional Information

Standard Configuration:

- CNC system: DA52 up, Delem (Holland) / DNC880S, Cybelec (Switzerland) / ESA S530 (Italy)

- Electrical-hydraulic proportional synchronous valve group: Hoerbiger/Bosch (Germany)

- Main electrical components: Schneider

- Optical scale: Givi (Italy)

- Gear pump with low noise: Nachi (Japan)

- Main oil cylinder seal ring: NOK (Japan)

- Ball screw and linear guide: Taiwan

- Electrical cabinet wind cooling

Options Available:

- Throat depth

- Top and bottom tools

- Back gauge with R, Z axis

- Light curtain

- Oil cooler/warmer

- CE certificate