Description

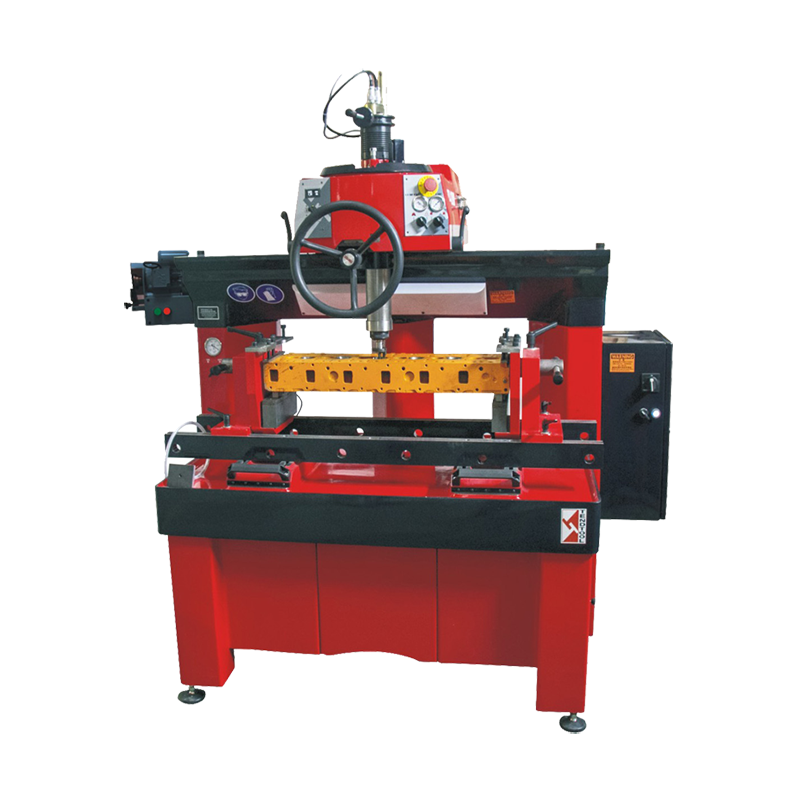

The CNC Valve Seat Boring Machine TL120CNC is a state-of-the-art high precision machine designed specifically for the repair of small motorcycle and automotive multivalve cylinder heads. Incorporating the latest technology, it features air-float automatic centering and a motor spindle for enhanced performance. The air-floated table fixture allows for flexible movement of the workpiece, ensuring versatility in processing various cylinder head types.

With its modern lightweight design and high strength, the TL120CNC emphasizes stability and precision. The machine includes a customized high-performance control system with a self-adaptive triple air cushion boring work head, built-in high torque motor, and an intuitive touch screen interface, making operation simple and efficient. Its “JOG” feature allows users to easily control spindle rotation, reducing blind spots for safe operation.

Additionally, the TL120CNC offers two cutting modes—general and step cutting—tailored to different seat materials, which addresses the limitations of traditional valve seat cutting machines. The manual step feeding function and high precision electronic pulse handwheel provide enhanced user control, making the machine more labor-saving and user-friendly. Furthermore, the innovative clamping system allows for workpiece rotation from -45° to +45°, featuring multiple clamping fixtures for rapid and secure setup.

Specifications

| Machine Capabilities | Unit | TL120CNC |

|---|---|---|

| Max. length of the cylinder head | mm/inch | Unlimited |

| Max. width of the cylinder head | mm/inch | 500/19.7 |

| Max. height of the cylinder head | mm/inch | 450/17.7 |

| Crosswise work piece tilting | degrees | +45° to -15° |

| Maximum table horizontal travel | mm/inch | 160/4.3 |

| Machining capacity dia. (min-max) | Φmm/inch | 16/120/0.6-4.7 |

| Lengthwise work head displacement | mm/inch | 990/39 |

| Crosswise work head displacement | mm/inch | 40/1.6 |

| Sphere-Cylinder travel | mm/inch | 9/0.4 |

| Max. spindle inclination | degrees | 5 |

| Spindle travel | mm/inch | 200/8 |

| Power of the spindle | KW | 2.2 |

| Spindle rotation speed | rpm | 0-1000 |

| Electric supply | V | 380V/50Hz 3ph or 220V/60Hz/3ph |

| Air pressure | bar/psi | 6-87 |

| Max. air flow | 1/mn-CFM | 300/11 |

| Level of noise at 400 RPM | dba | 72 |

| Level of noise at 1200 RPM | dba | 82 |

| Net weight (approx.) | kg/lbs | 1420/3130 |

| Machine space requirements: Length | mm/inch | 1750/68.9 |

| Machine space requirements: Width | mm/inch | 1150/45.3 |

| Machine space requirements: Height | mm/inch | 2200/86.6 |

Additional Information

Standard Accessories:

- Bit holder

- Tool holder

- Pilot

- Bits

- Tool setting device

- Sharpener

- Clamping system

Optional Accessories:

- TD-ER20SW spanner wrench

- TD-ER20SC spring collet

- T3200 Adaptor for morse

- T3100 Precision chuck with MT2 shank

- TENDTOOL REAMER RN Type

- TD-ER20CN ER-32 clamping nut