Description

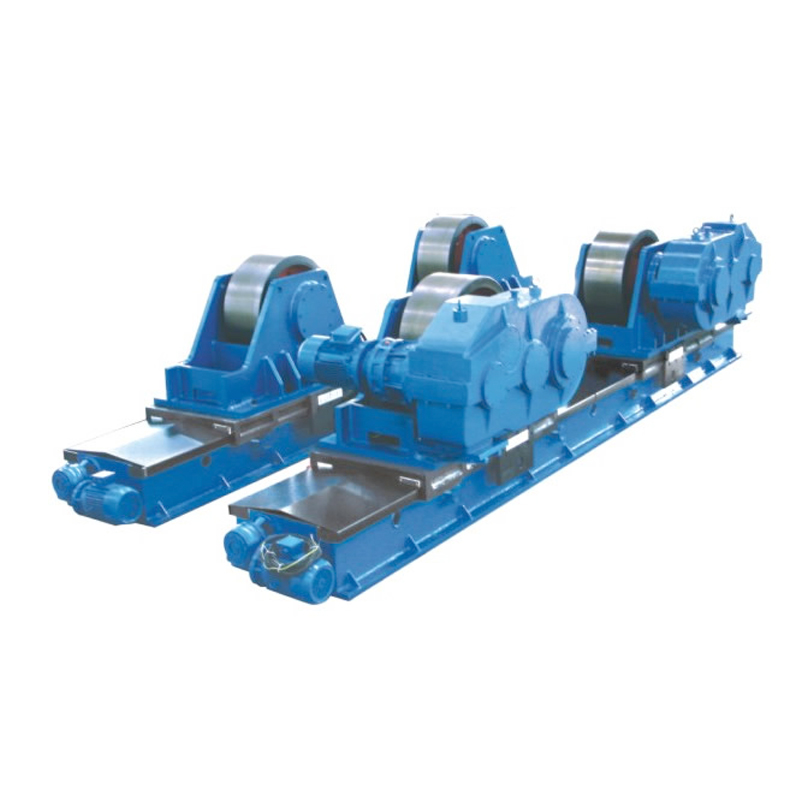

The Conventional Welding Rotator is an essential tool for precise welding operations, designed to accommodate various diameters of workpieces. This robust equipment features both a power and an idle roller, allowing for adjustable center distances to meet specific welding needs. The frequency speed adjustment transmission mechanism ensures optimal performance and adaptability.

This welding rotator is composed of a driving roller frame, idler roller frame, driving reducer system, and a control system. The rollers are equipped with durable steel wheels, offering exceptional bearing capacity and strong driving capabilities for reliable operation. The structural components are carefully annealed after welding and reprocessed for extended service life and consistent performance.

With a design that prioritizes stability, the welding rotator operates smoothly at rated working speeds, minimizing slip and mechanical shock. It is engineered to accommodate loads up to 40 tons, ensuring that all operational demands are met without compromise.

Specifications

| Attribute | Description |

|---|---|

| Max Load Capacity | 40T (optional) |

| Suitable Workpiece Range | ф600-ф4200mm (optional) |

| Rubber Roller Diameter | ф400 × 120 (optional) |

| Metal Roller Diameter | 2 × ф390 × 40 (optional) |

| Roll Linear Speed | 6-60 m/h |

| Speed Adjustment Mode | Frequency stepless speed adjustment |

| Motor Power | 2*1.5KW (optional) |

Additional Information

- This welding rotator is ideal for various welding applications requiring precise control and stability.

- Regular maintenance is recommended to ensure optimal performance and longevity.