Description

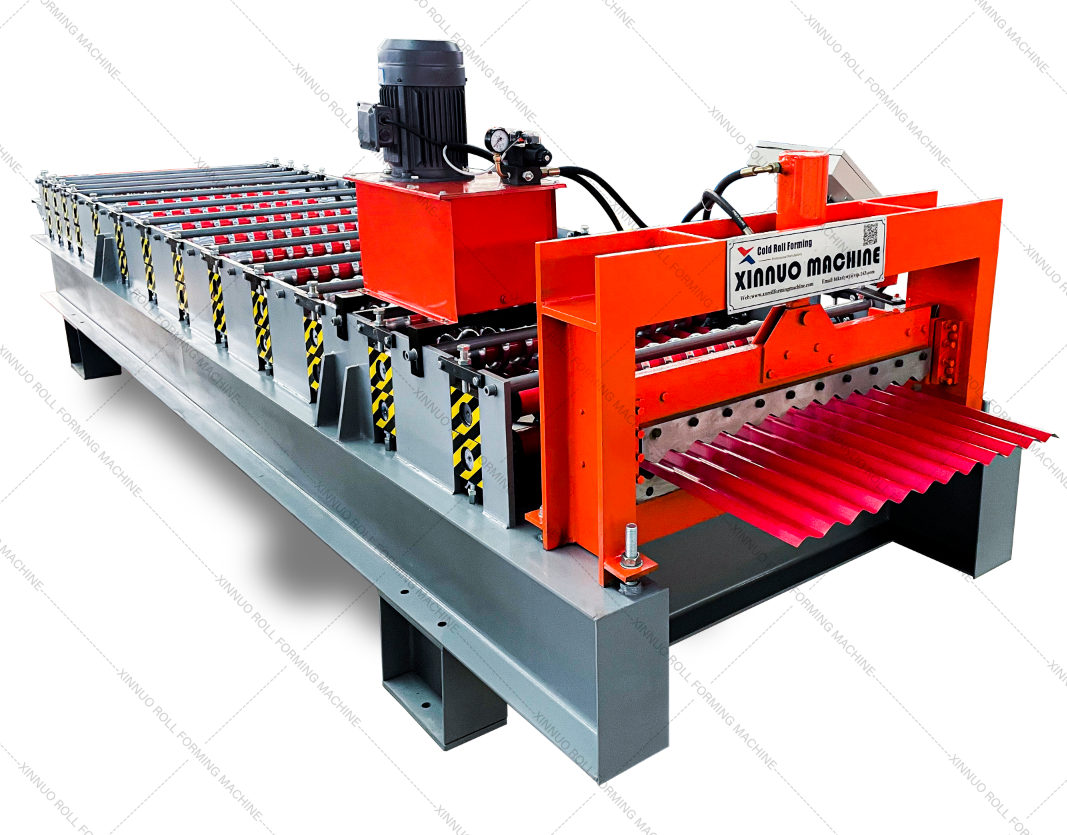

The Corrugated Iron Sheet Making Aluzinc Roll Forming Machine is a state-of-the-art equipment designed for the efficient production of corrugated iron sheets. This machine excels in processing color steel plates with a width of 1000mm and a thickness range of 0.3-0.8mm. It features a manual de-coiler capable of handling up to 5 tons of raw material, ensuring smooth operations during the manufacturing process. The machine is equipped with 14 rows of forming rollers, allowing for precise shaping of sheets, and utilizes a hydraulic cutting method for clean and accurate results. With a main motor power of 4kw and a hydraulic cutting power of 3kw, it achieves a productivity rate of 8-12 meters per minute. The robust design and construction ensure durability and long-term performance.

Specifications

| Attribute | Details |

|---|---|

| Suitable to Process | Color Steel Plate |

| Width of the Plate | 1000mm |

| Thickness of the Plate | 0.3-0.8mm |

| De-coiler | Manual, can load 5 tons raw material |

| Rollers for Forming | 14 rows |

| Diameter of the Roller | 80mm |

| Rolling Material | Carbon Steel 45# |

| Main Motor Power | 4kw |

| Productivity | 8-12m/min |

| Cutting Method | Hydraulic mould cutting |

| Material of the Cutting Blade | Cr12 |

| Hydraulic Cutting Power | 3kw |

| Processing Precision | Within 1.00mm |

| Control System | Delta PLC control |

| Side Panel of Machine | 14mm |

| Main Structure of the Machine | 300 H Steel |

| Weight | About 4.6T |

| Dimensions | 7.5*1.6*1.2m |

| Voltage | 380V 50Hz 3phases (changeable as needed) |

| Certificate | CE/ISO |

Packing & Delivery

| Packaging Details | Main machine is nude, the computer control box is packed with a wooden frame. |

| Delivery Detail | 20 days |