Description

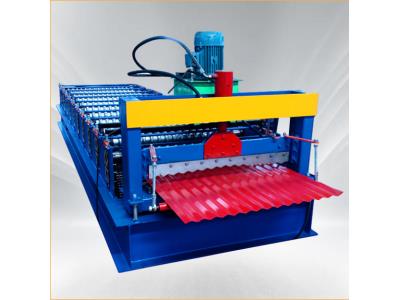

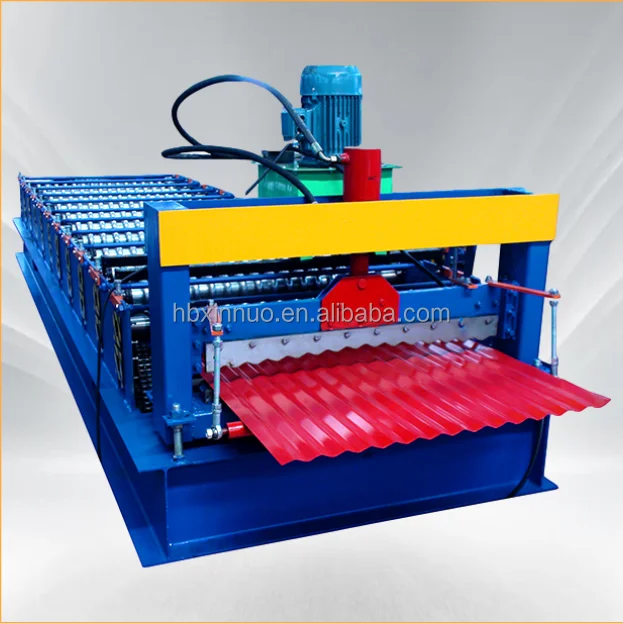

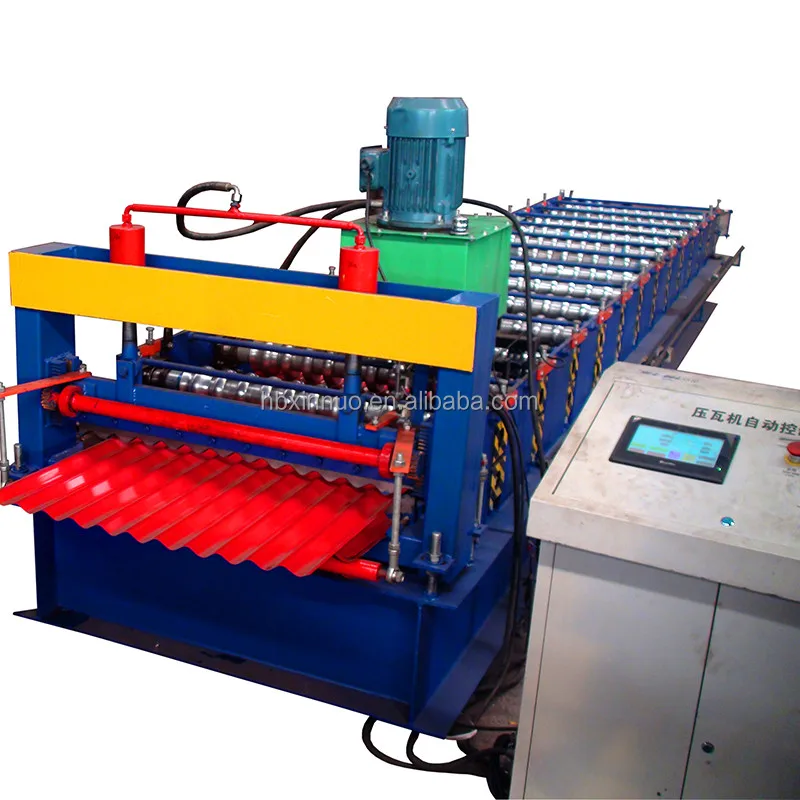

The Aluzinc Roll Forming Machine is a cutting-edge solution designed for the efficient production of corrugated iron sheets. This machine is engineered to process color steel plates with precision, allowing for a variety of applications in construction and manufacturing. With its robust design and advanced technology, it features a manual de-coiler capable of loading up to 5 tons of raw material, 14 rows of rollers for forming, and a hydraulic mold cutting method for optimal performance. The machine is built to ensure high productivity and reliability, making it an essential asset for any metalworking operation.

Specifications

| # | Specification | Details |

|---|---|---|

| 1 | Suitable to process | Color steel plate |

| 2 | Width of the plate | 1000mm |

| 3 | Thickness of the plate | 0.3-0.8mm |

| 4 | De-coiler | Manual, can load 5 tons raw material |

| 5 | Rollers for forming | 14 rows |

| 6 | Diameter of the roller | 80mm |

| 7 | Rolling material | Carbon Steel 45# |

| 8 | Main motor power | 4kw |

| 9 | Productivity | 8-12m/min |

| 10 | Cutting method | Hydraulic mould cutting |

| 11 | Material of the cutting blade | Cr12 |

| 12 | Hydraulic cutting power | 3kw |

| 13 | Processing precision | Within 1.00mm |

| 14 | Control system | Delta PLC control |

| 15 | Side panel of machine | 14mm |

| 16 | Main structure of the machine | 300 H steel |

| 17 | Weight | About 4.6T |

| 18 | Dimensions | 7.5*1.6*1.2m |

| 19 | Voltage | 380V 50Hz 3phases(changeable as needed) |

| 20 | Certificate | CE/ISO |

Additional Information

Packing Details: The main machine is nude in the container, whereas the computer control box is packed with wooden packaging.

Delivery Detail: 20 days.