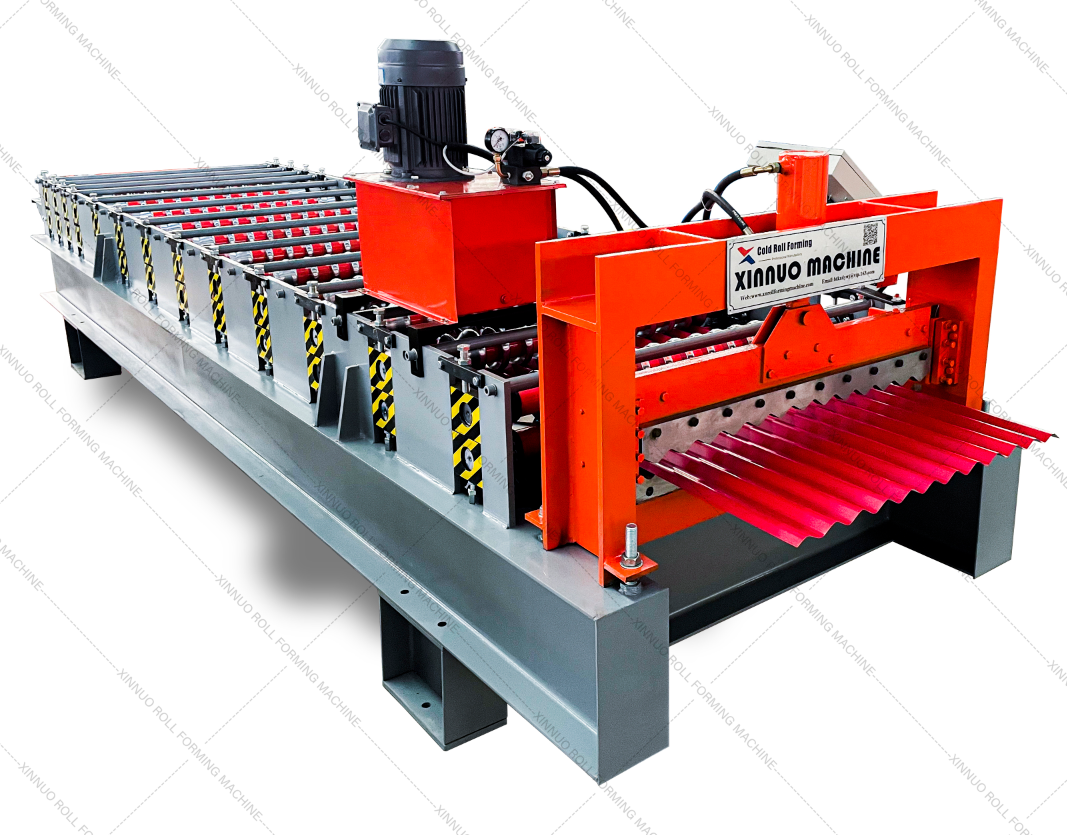

corrugated iron sheet making aluzinc roll forming machine

Inquire NowDescription

The Corrugated Iron Sheet Making Aluzinc Roll Forming Machine is an advanced piece of equipment designed for the efficient production of corrugated iron sheets. This machine is specifically suitable for processing color steel plates, combining precision engineering with robust construction to ensure high-quality output. With a productivity rate of 8-12 meters per minute, this roll forming machine is perfect for both small-scale and large-scale operations, making it an essential tool for manufacturers in the industry.

Equipped with a manual de-coiler that can handle up to 5 tons of raw material, the machine features 14 rows of forming rollers, ensuring consistent and precise shaping of sheets. Its user-friendly Delta PLC control system enhances operational ease, while the hydraulic mould cutting method provides clean and accurate cuts.

Specifications

| Attribute | Details |

|---|---|

| Suitable to process | Color steel plate |

| Width of the plate | 1000 mm |

| Thickness of the plate | 0.3-0.8 mm |

| De-coiler | Manual, can load 5 tons raw material |

| Rollers for forming | 14 rows |

| Diameter of the roller | 80 mm |

| Rolling material | Carbon Steel 45# |

| Main motor power | 4 kW |

| Productivity | 8-12 m/min |

| Cutting method | Hydraulic mould cutting |

| Material of the cutting blade | Cr12 |

| Hydraulic cutting power | 3 kW |

| Processing precision | Within 1.00 mm |

| Control system | Delta PLC control |

| Side panel of machine | 14 mm |

| Main structure of the machine | 300 H steel |

| Weight | About 4.6 T |

| Dimensions | 7.5 x 1.6 x 1.2 m |

| Voltage | 380V 50Hz 3 phases (changeable as needed) |

| Certificate | CE/ISO |

Packing & Delivery

| Packaging Details: | Main machine is nude, the computer control box is packed with a wooden frame. |

| Delivery Detail: | 20 days |