corrugated iron sheet making aluzinc roll forming machine

Inquire NowDescription

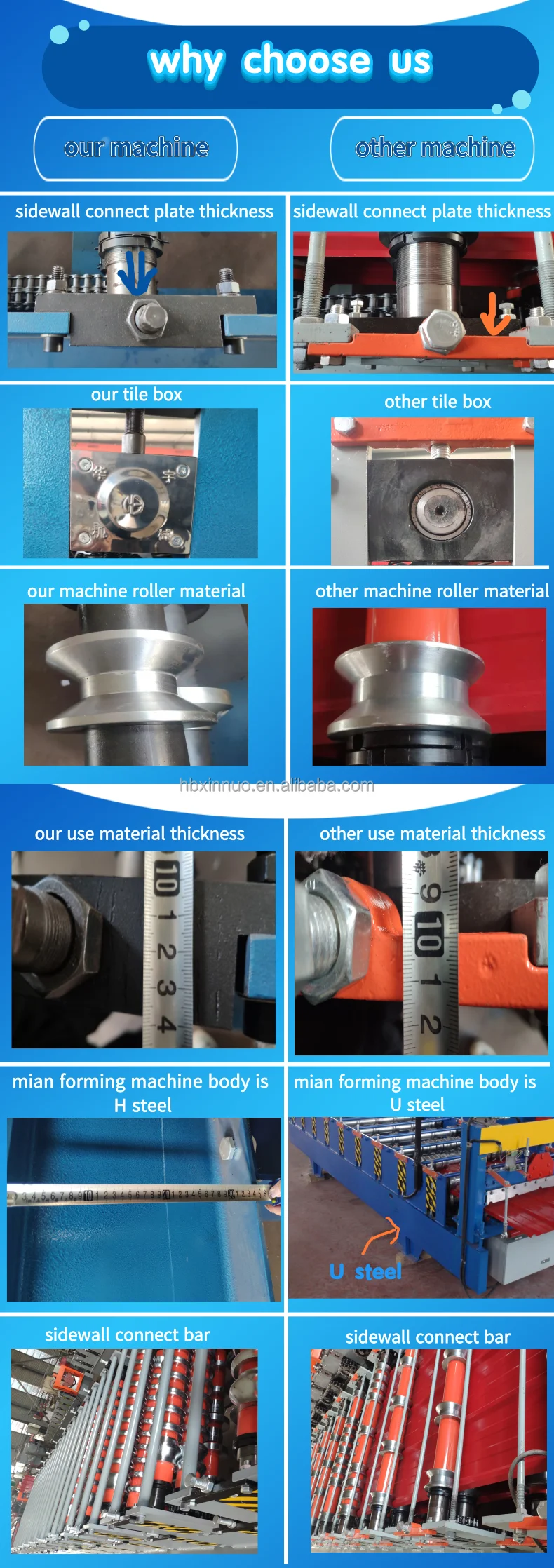

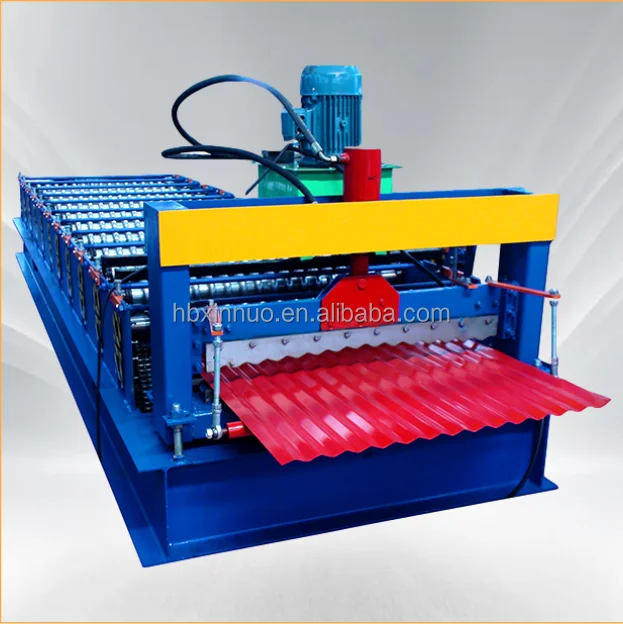

The corrugated iron sheet making aluzinc roll forming machine is a highly efficient and versatile tool designed for producing quality corrugated sheets. This machine is tailored to process color steel plates, making it an ideal choice for manufacturers in the construction and roofing industries. With its advanced features, including a manual de-coiler capable of holding up to 5 tons of raw material, 14 forming rollers, and a hydraulic mould cutting method, this machine guarantees precision and speed.

Engineered for durability, this machine boasts a main structure made from robust 300 H steel and is powered by a 4kw motor, allowing for a productivity rate of 8-12 meters per minute. Additionally, it supports a plate thickness range of 0.3-0.8mm, making it suitable for a wide variety of applications. The Delta PLC control system ensures ease of operation and accuracy, while the cutting blade made from Cr12 material enhances longevity and performance.

Specifications

| Attribute | Details |

|---|---|

| Suitable to process | Color steel plate |

| Width of the plate | 1000mm |

| Thickness of the plate | 0.3-0.8mm |

| De-coiler | Manual, can load 5 tons raw material |

| Rollers for forming | 14 rows |

| Diameter of the roller | 80mm |

| Rolling material | Carbon Steel 45# |

| Main motor power | 4kw |

| Productivity | 8-12m/min |

| Cutting method | Hydraulic mould cutting |

| Material of the cutting blade | Cr12 |

| Hydraulic cutting power | 3kw |

| Processing precision | Within 1.00mm |

| Control system | Delta PLC control |

| Side panel of machine | 14mm |

| Main structure of the machine | 300 H steel |

| Weight | About 4.6T |

| Dimensions | 7.5*1.6*1.2m |

| Voltage | 380V 50Hz 3phases (changeable as needed) |

| Certificate | CE/ISO |

Packing & Delivery

Packaging Details: The main machine is nude, while the computer control box is packed with a wooden frame. The main machine is securely placed in the container for safe transport.

Delivery Detail: Estimated delivery time is 20 days.