Description

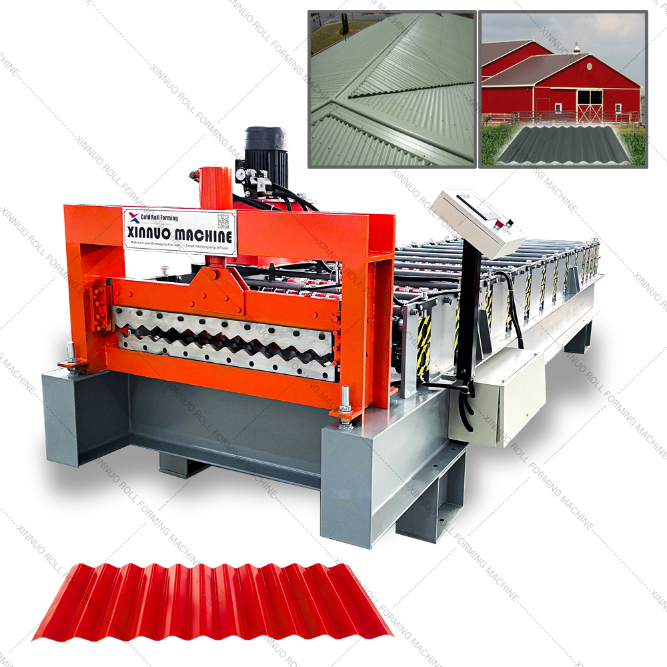

The Corrugated Roof Profile Making Machine is designed to efficiently produce high-quality corrugated metal roofing sheets. With a robust construction and advanced technology, this machine is capable of handling full hard 0.15mm GI materials. It integrates multiple functionalities including a manual uncoiler, guiding platform, coil strip leveler, and a main roll forming machine, ensuring a seamless production process. The machine is powered by a reliable PLC Delta Inverter control system, enabling precision and automation in operations.

Specifications

| Attribute | Details |

|---|---|

| Configurations | Manual Uncoiler, Guiding Platform, Coil Strip Leveler, Main Machine of Roll Forming, Electro-Motor, Cutting Device, Hydraulic Station, PLC Control, Supporter Table. |

| Control System | PLC Delta Inverter |

| Main Frame | 250mm H-Beam |

| Main Power | 3 kW |

| Pump Power | 3 kW |

| Power Supply | 380V, 3-Phase, 50Hz |

| Forming Speed | 10 m/min |

| Roll Station | 14 stands |

| Roller Diameter | 80 mm |

| Hydraulic Pressure | 10-12 MPa |

| Forming Size | 988 mm |

| Feeding Thickness | 0.3-0.8 mm |

| Feeding Width | 1200 mm |

| Backboard Thickness | 14 mm |

| Chain Size | 20 mm |

| Cutter Standard | Cr12 |

| Roller Standard | Cr12 |

| Cr-Plating Size | 0.05 mm |

| Overall Size | 7500×1600×1500 mm |

| Total Weight | 4 T |

Additional Information

For optimal performance, ensure regular maintenance of the machine and adherence to operational guidelines. This machine is suitable for various roofing applications and can enhance production efficiency in roofing sheet manufacturing.