Description

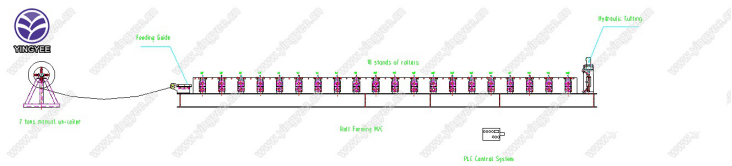

The Corrugated Roof Sheet Roll Forming Machine is a state-of-the-art equipment designed to produce high-quality corrugated roofing sheets efficiently. Operating at a speed of 15m/min, this machine utilizes a hydraulic cutting system for precise operations, ensuring that each sheet meets the highest standards of quality. Crafted for versatility, the machine can handle various materials, including PPGI, GI, and aluminum, with a thickness ranging from 0.2mm to 0.8mm. It boasts a robust PLC control system, allowing for seamless automation and ease of use.

This machine comprises essential components such as a manual coiler, adjustable input equipment, and a main roll forming machine constructed with a chromed plate for durability. With a total of 13 roll stations, it guarantees consistent performance while producing sheets tailored to specific dimensions as per client drawings.

Specifications

| Attribute | Details |

|---|---|

| Matching Material | PPGI/GI/Aluminium |

| Material Thickness | 0.2 – 0.8 mm |

| Power | 5.5 kW |

| Forming Speed | 15 m/min and 30 m/min |

| Width of Plates | According to drawings |

| Input Leveling Equipment | Adjustable |

| Roll Stations | 13 |

| Shaft Material and Diameter | 45# steel, ¢75mm |

| Tolerance | 10m ± 1.5mm |

| Drive Method | Chain driven |

| Controlling System | PLC |

| Voltage | Depends on client |

| Material of Forming Rollers | 45# steel, heat treated and chromed |

| Side Plate | Steel plate with chrome |

| Size | Length: 6.7m, Weight: 5 tons |

Additional Information

- Hydraulic Cutter: Ensures precise cutting for high-quality sheets.

- Adjustable Input Equipment: Customizable for various sheet sizes.

- Durable Construction: Built with chromed plates and quality materials for longevity.