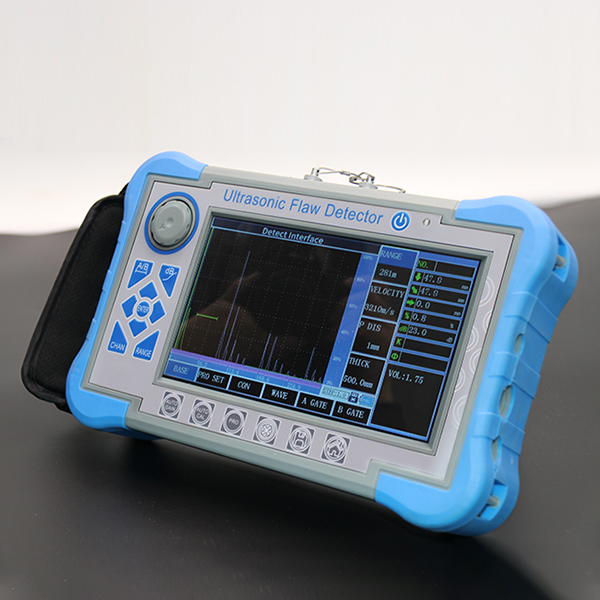

OEM ODM Digital Ultrasonic Flaw Detector

Description

The Digital Ultrasonic Flaw Detector is a state-of-the-art device designed for precise non-destructive testing. Featuring an intuitive touch screen interface, this advanced flaw detector allows for quick, easy, and accurate identification of internal defects in various materials, such as cracks, welds, pores, and inclusions, without causing any damage. Ideal for use in sectors such as electric power, petrochemical, aerospace, automotive, and military, this instrument is essential for ensuring safety and quality in critical applications.

With its high-precision quantitative positioning capabilities, the device meets the detection requirements for both near and far distances, making it particularly effective for small-diameter and thin-walled pipes. The auto-calibration function and automatic defect echo position display further enhance its usability, while features like auto gain, peak memory functions, and the ability to store and playback A-scan waves significantly improve detection efficiency.

Specifications

| Attribute | Details |

|---|---|

| Display | 7 inch TFT color screen, 800×480 resolution |

| Operation mode | Button, Rotary, Touch Screen |

| Power supply | Lithium Ion Battery |

| Battery capacity | 5.0Ah |

| Power voltage | 12V |

| Working time | ≥8 hours |

| Dimension | 245 x 155 x 55 mm |

| Weight | 1.18 kg (including battery) |

| IP Grade | IP65 |

| Working Temperature | -10℃ to 45℃ |

| Storage Temperature | -20℃ to 60℃ |

Additional Information

This device is equipped with multiple features like communication software for data analysis and report printing, a high-performance lithium battery for extended use, and real-time clock recording for flaw detection date and time tracking. With its durable ABS plastic shell, it is designed to withstand challenging environments, making it a reliable choice for professionals in the non-destructive testing field.