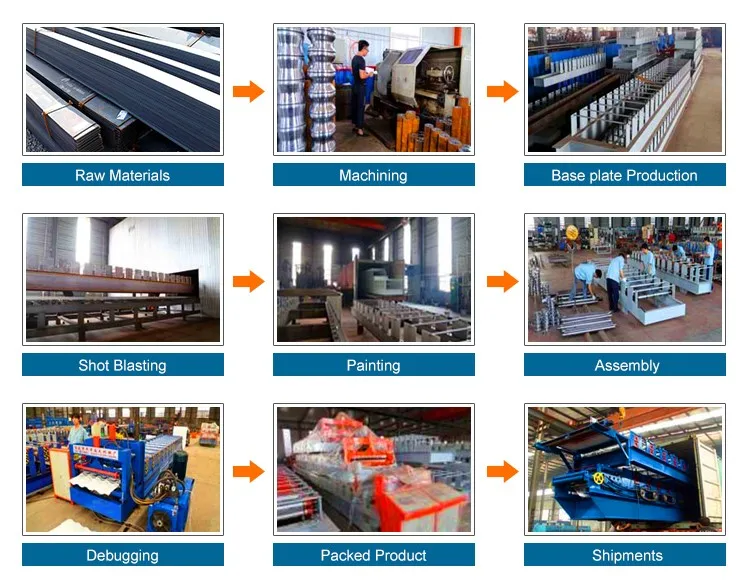

OEM ODM Double Layer Corrugated Metal Roofing Sheet Roll Forming Machine IBR Roofing panel double

Description

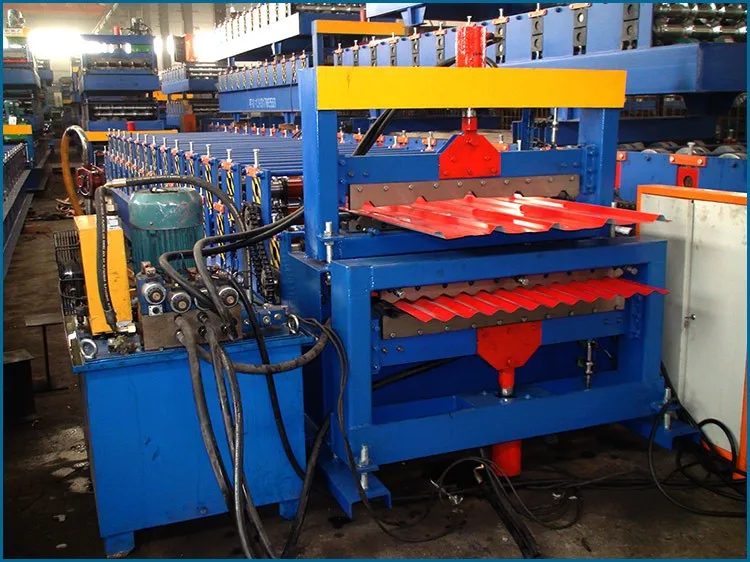

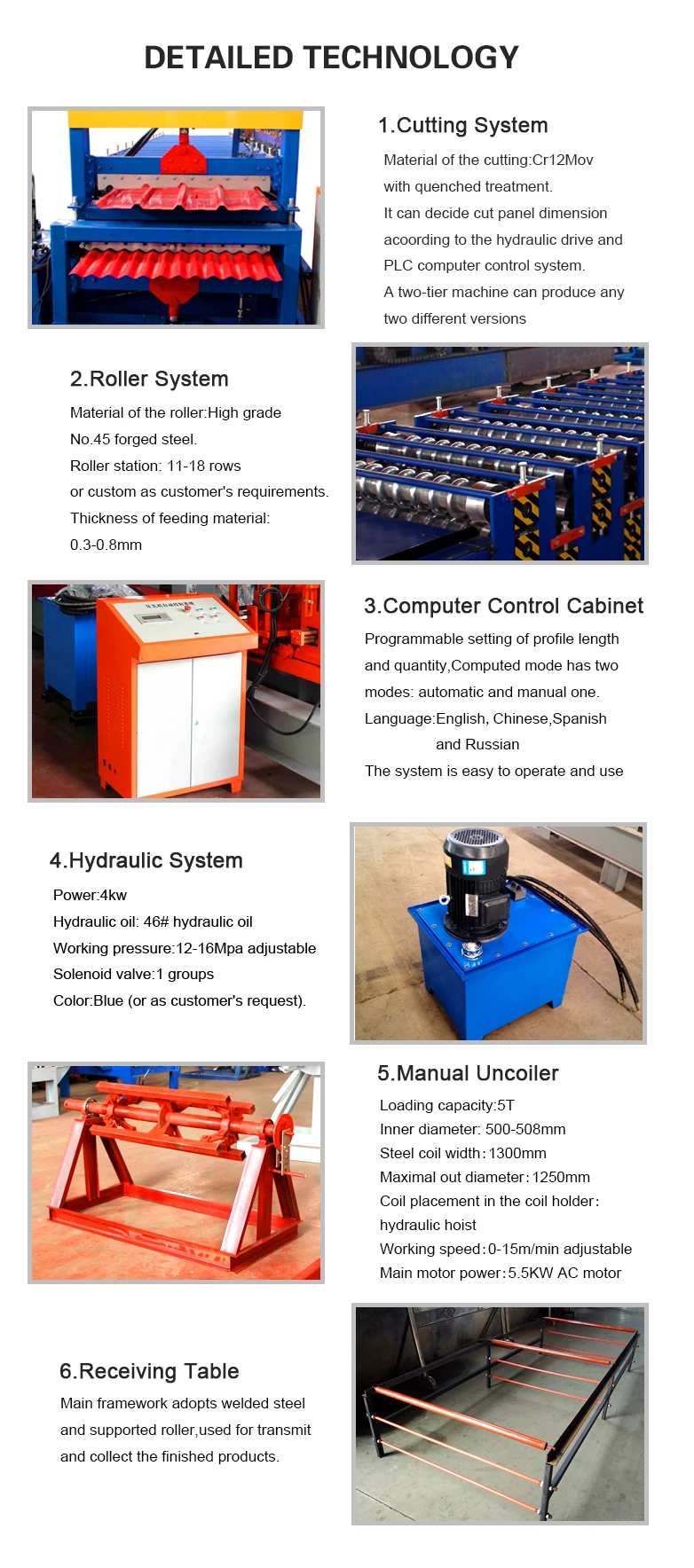

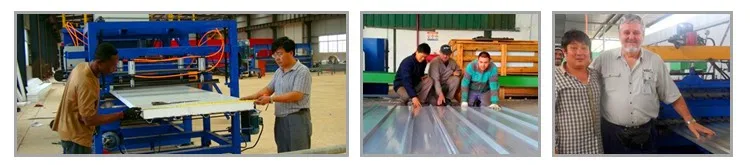

The Double Layer Corrugated Metal Roofing Sheet Roll Forming Machine is an innovative solution designed for producing IBR roofing panels efficiently. This machine is capable of processing a variety of materials including color steel plates, galvanized sheets, and aluminum coils. With its advanced design, it allows manufacturers to create durable, high-quality roofing sheets tailored to specific requirements.

This machine features a dual-layer system, enabling the production of two different profiles without the need for extensive reconfiguration. Its robust construction ensures longevity, while the ability to customize roller stations according to customer specifications enhances operational flexibility.

Specifications

| Parameter | Details |

|---|---|

| Suitable to process | Color steel plate, galvanized sheet, aluminum coils, etc. |

| Width of the feeding material | 914-1250mm |

| Roller station | 11-18 rows or custom as customer’s requirements |

| Thickness of feeding material | 0.3-0.8mm |

| Productivity | 8-12m/min |

| Rollers’ material | 45# steel |

| Diameter of shaft | 70-80mm |

| Voltage | 380V 50Hz 3 phases |

| Wall thickness of main forming machine | 12-18mm steel plate |

| Main forming machine body | 300-400 mm H steel |

| Motor power | 4-7.5 kw |

| Weight | About 5-15T |

| Custom | According to customer’s requirements |

Additional Information

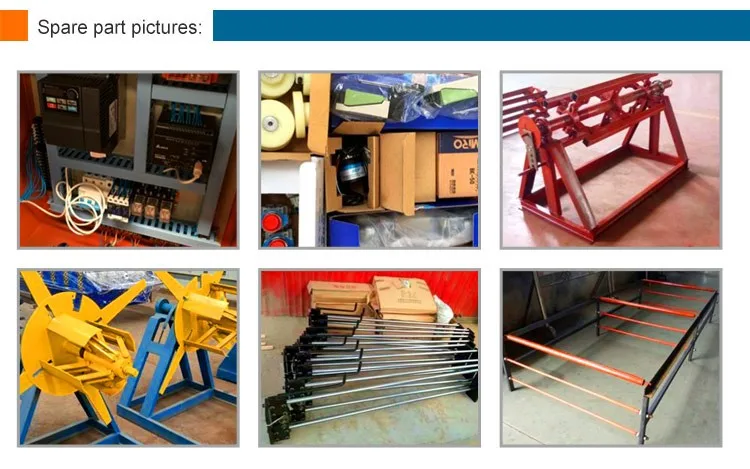

Guarantee: 12 Months guarantee. If any part of the machine is broken, replacement parts will be provided. However, if the damage is due to operational errors, the buyer will be responsible for shipping costs.

After-sale service: Technicians can be sent to your location for repairs. The buyer is responsible for all costs, including visa, roundtrip tickets, accommodation, and a daily salary of $100.