Double Layer Corrugated Metal Roofing Sheet Roll Forming Machine IBR Roofing panel double

Inquire NowDescription

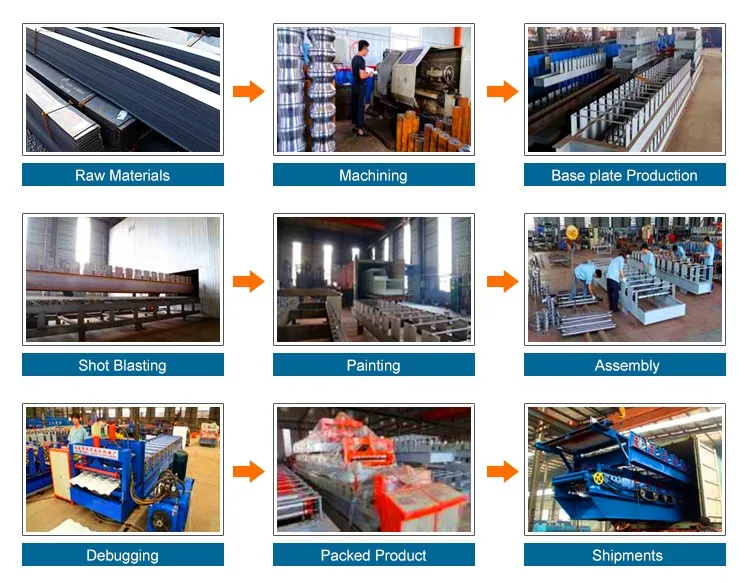

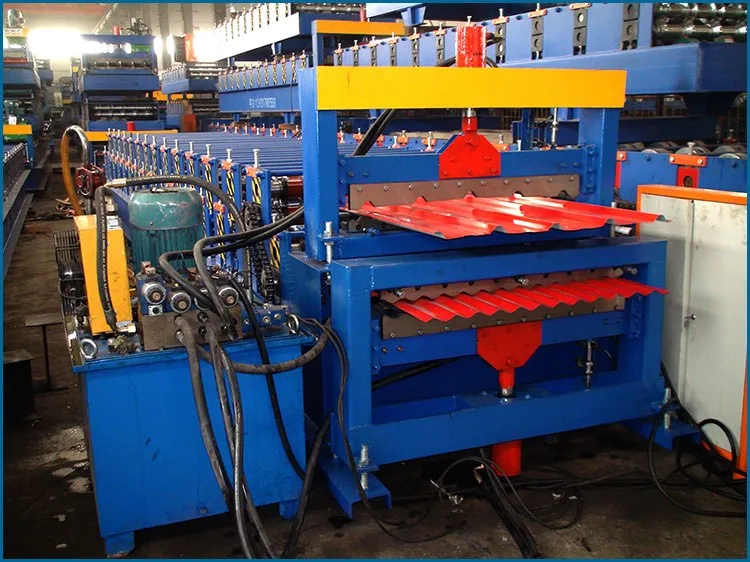

The Double Layer Corrugated Metal Roofing Sheet Roll Forming Machine is designed for efficient production of IBR roofing panels. This advanced machine allows for the processing of various materials, including color steel plates, galvanized sheets, and aluminum coils. It features a double layer design, increasing productivity and versatility in roofing applications. The machine is engineered for reliability and precision, making it an essential tool for construction and manufacturing industries.

Specifications

| Parameter | Description |

|---|---|

| Suitable to process | Color steel plate, galvanized sheet, aluminum coils, etc. |

| Width of feeding material | 914-1250mm |

| Roller station | 11-18 rows or custom as customer’s requirements |

| Thickness of feeding material | 0.3-0.8mm |

| Productivity | 8-12m/min |

| Rollers’ material | 45# steel |

| Diameter of shaft | 70-80mm |

| Voltage | 380V 50Hz 3 phases |

| Wall thickness of main forming machine | 12-18mm steel plate |

| Main forming machine body | 300-400 mm H steel |

| Motor power | 4-7.5 kw |

| Weight | About 5-15T |

| Custom | According to customer’s requirements |

Additional Information

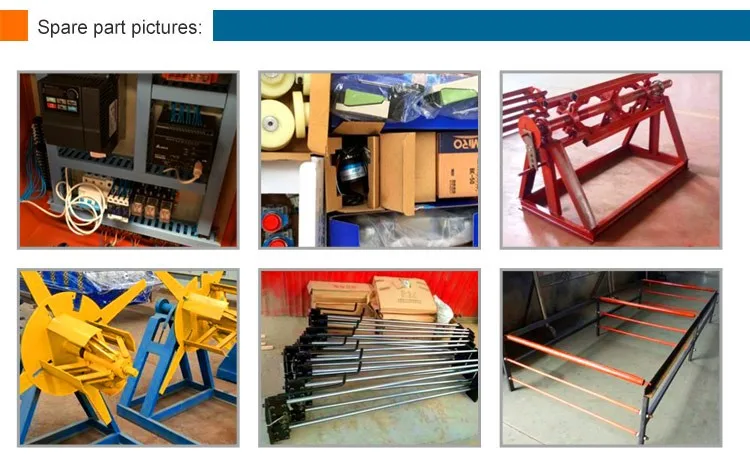

Guarantee: 12 Months guarantee. If any part of the machine is broken, we will supply the best part. However, if the damaged parts are due to operational error, the buyer will pay for the shipping fee.

After-sale service: We send technicians to your country to fix the machine. The buyer should bear all costs including visa, round-trip ticket, suitable accommodation, and a salary of $100 per day for the technician.