double layer roll forming machine roof sheet roll forming machine wellding Tile Making

Inquire NowDescription

The double layer roll forming machine is engineered for the efficient production of roof sheets and tiles, combining two types of tiles in one robust design. This advanced machine showcases a reasonable structure and an attractive appearance, making it ideal for those with limited operational space. It is particularly well-received by customers looking for versatility and efficiency in their production processes.

Specifications

| Feature | Details |

|---|---|

| Control System | Automatic PLC frequency control with text screen |

| Roller Steps | 9/11 rows |

| Main Power | 4 kW |

| Pump Power | 4 kW |

| Diameter of Roller | Φ72 mm |

| Max Speed | 12 m/min |

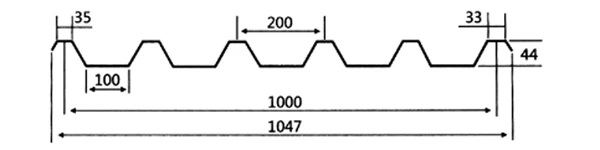

| Feeding Width | 1000 mm |

| Effective Width | 850/840 mm (tolerance ±1/100) |

| Plate Thickness | 0.35-0.6 mm |

| Dimension of Main Roll Former | 7600 mm × 1300 mm × 1450 mm |

| Roller Material | 45# steel, CNC-machined, heat treated, buffed, electroplated chromium 0.05 mm |

Additional Information

The double layer roll forming machine is widely applicable in various sectors, including industrial factories, civilian buildings, warehouses, and lightweight steel structures. It is designed to provide a durable and aesthetically pleasing finish, meeting the demands of modern construction and manufacturing.

Packaging Details: The main machine is shipped nude, while the computer control box is securely packed in a wooden frame.

Delivery Detail: Estimated delivery within 20 days.

Guarantee: 12 months warranty on parts, with conditions for replacements based on operational errors.

Images