Description

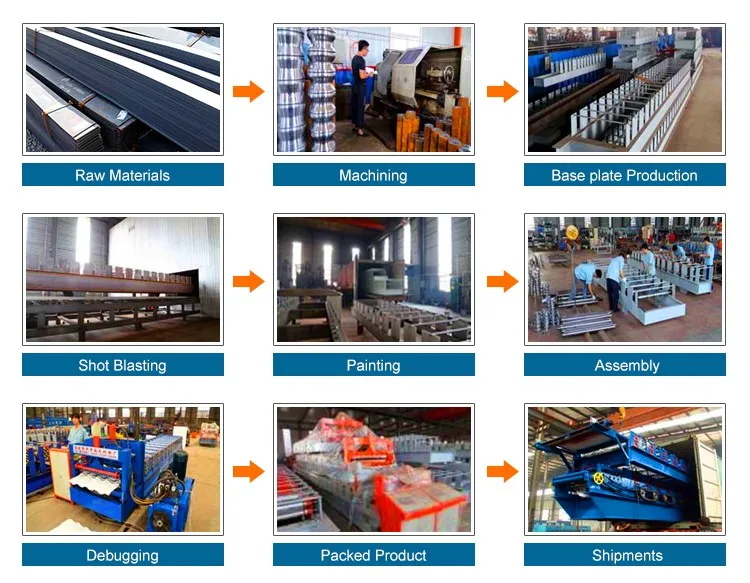

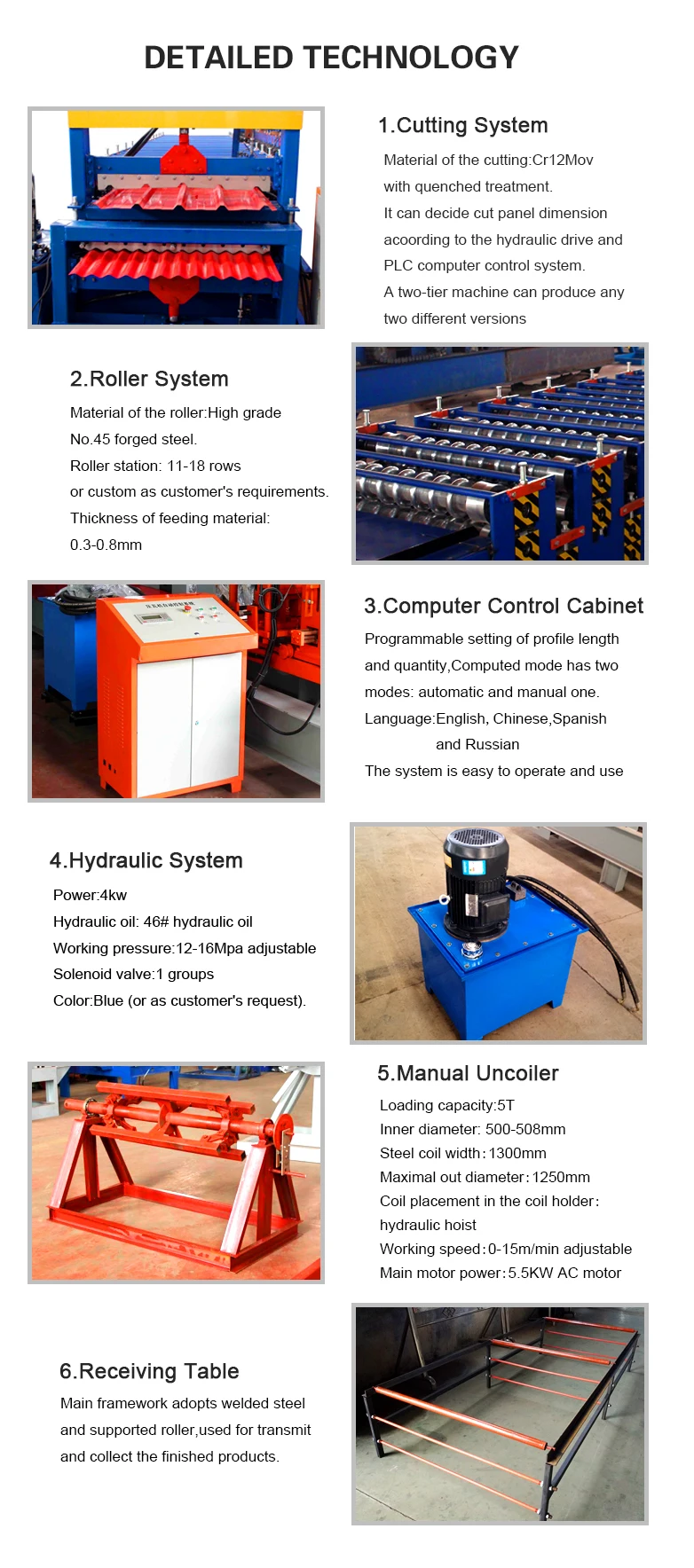

The double layer roof panel double decker roll forming machine is an advanced solution for producing high-quality roofing sheets. Designed for efficiency and versatility, this machine can process a variety of materials, including color steel plates, galvanized sheets, and aluminum coils. With its robust construction and customizable features, it ensures durability and consistent performance in the manufacturing of double-layer metal roofing sheets.

Specifications

| Parameter | Description |

|---|---|

| Suitable to process | Color steel plate, galvanized sheet, aluminum coils, etc. |

| Width of the feeding material | 914-1250mm |

| Roller station | 11-18 rows or custom as customer’s requirements |

| Thickness of feeding material | 0.3-0.8mm |

| Productivity | 8-12m/min |

| Rollers’ material | 45# steel |

| Diameter of shaft | 70-80mm |

| Voltage | 380V 50Hz 3phases |

| Wall thickness of main forming machine | 12-18mm steel plate |

| Main forming machine body | 300-400 mm H steel |

| Motor power | 4-7.5 kw |

| Weight | About 5-15T |

| Custom | According to customer’s requirements |

Additional Information

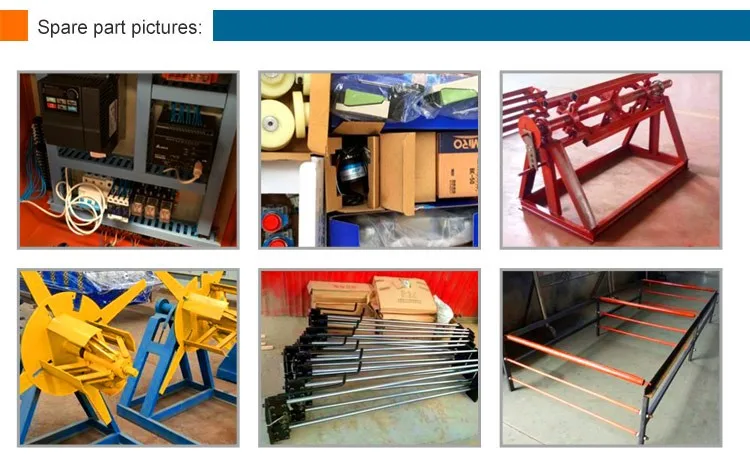

Guarantee: 12 Months guarantee. If any part of the machine is broken, we will supply the best part; however, if the damaged parts are due to operator error, the buyer will pay for the shipping fee.

After-sale service: Technicians can be sent to your country to fix the machine. The buyer should bear all costs, including visa, round-trip ticket, and suitable accommodation, as well as pay a salary of 100 USD/day.