Description

The double layer roof tile making machine is an advanced roll forming machine designed for efficiency and precision in producing high-quality roofing tiles. Capable of processing various materials such as color steel plates, galvanized sheets, and aluminum coils, this machine is engineered to meet diverse production needs. It features a robust structure, multiple roller stations, and customizable specifications to accommodate different production requirements.

Specifications

| Attribute | Details |

|---|---|

| Suitable to Process | Color steel plate, galvanized sheet, aluminum coils, etc. |

| Width of Feeding Material | 914-1250mm |

| Roller Station | 11-18 rows or custom as customer’s requirements |

| Thickness of Feeding Material | 0.3-0.8mm |

| Productivity | 8-12m/min |

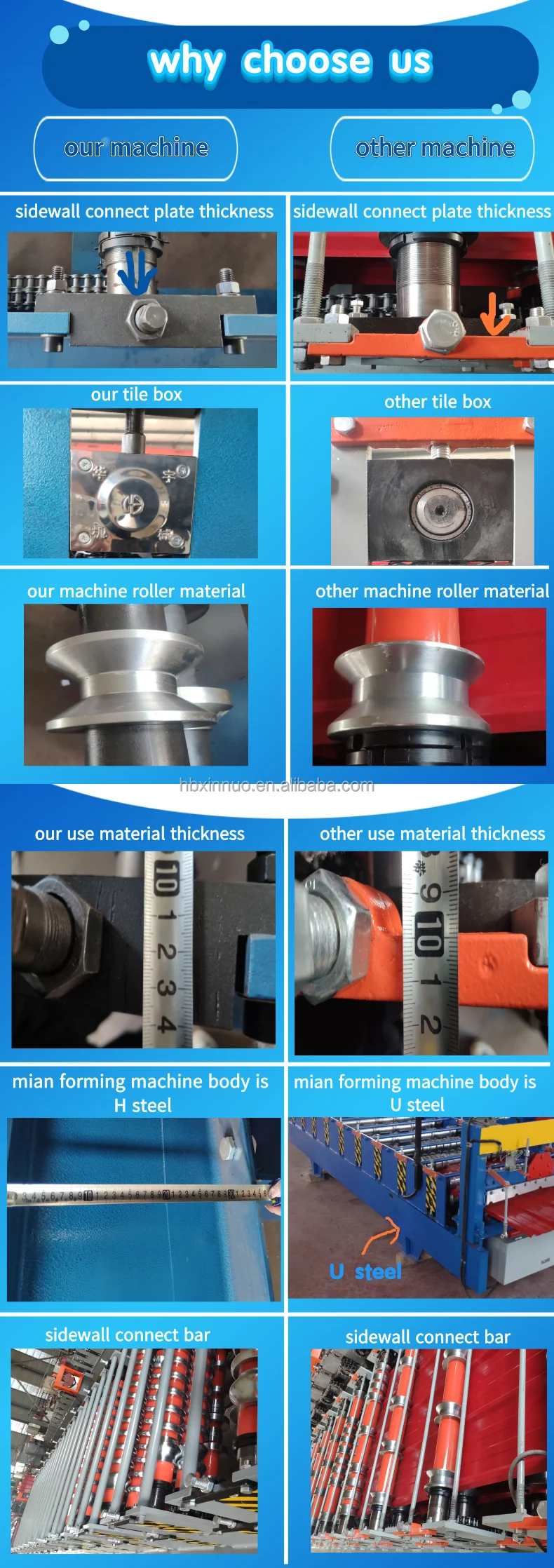

| Rollers’ Material | 45# steel |

| Diameter of Shaft | 70-80mm |

| Voltage | 380V 50Hz 3phases |

| Wall Thickness of Main Forming Machine | 12-18mm steel plate |

| Main Forming Machine Body | 300-400 mm H steel |

| Motor Power | 4-7.5 kw |

| Weight | About 5-15T |

| Custom Specifications | According to customer’s requirements |

Additional Information

Packing & Delivery:

| Packaging Details: | Main machine is nude, the computer control box is packed with a wooden frame. |

| Delivery Detail: | 20 days |