double layer roof tile making machine roll forming machine prices

Inquire NowDescription

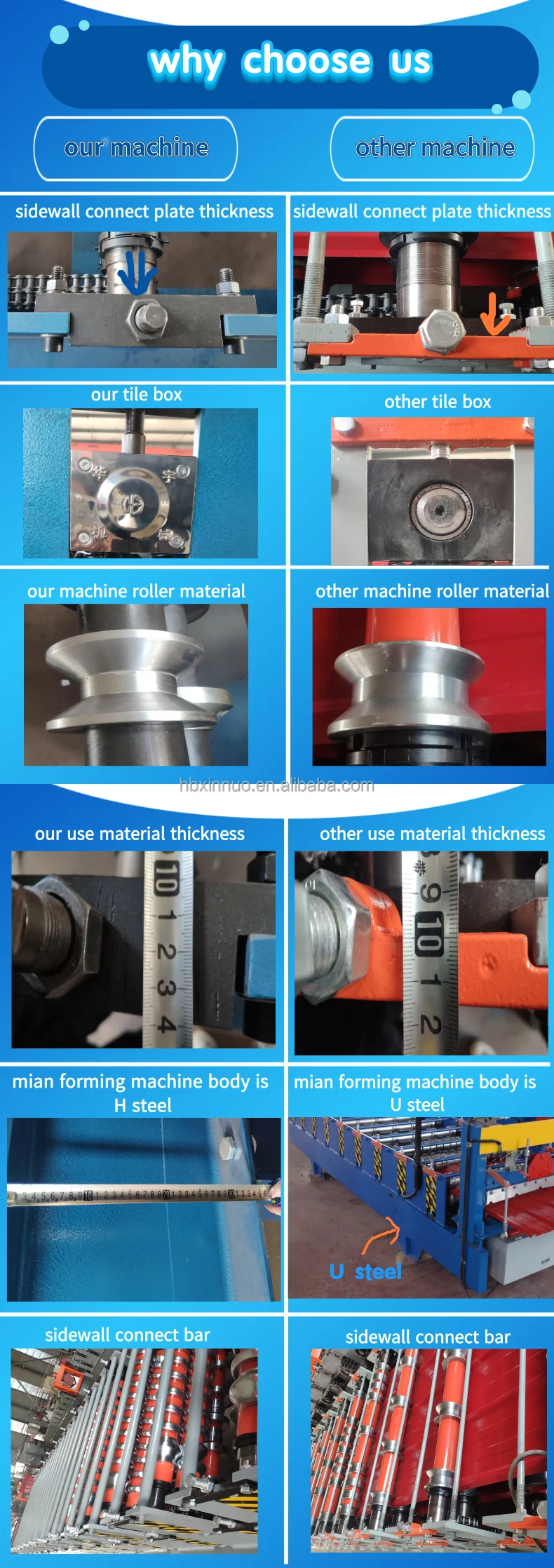

The double layer roof tile making machine is a robust roll forming machine designed for efficiency and versatility in producing high-quality roofing materials. This state-of-the-art equipment is ideal for processing various materials, including color steel plates, galvanized sheets, and aluminum coils. Its double-layer design allows for the simultaneous production of different tile profiles, maximizing productivity and reducing operational costs. The machine features advanced technology for precise shaping and cutting, ensuring that each tile meets the highest standards of quality and durability.

Specifications

| Attribute | Details |

|---|---|

| Suitable to Process | Color steel plate, galvanized sheet, aluminum coils, etc. |

| Width of Feeding Material | 914-1250 mm |

| Roller Station | 11-18 rows or custom as per requirements |

| Thickness of Feeding Material | 0.3-0.8 mm |

| Productivity | 8-12 m/min |

| Rollers’ Material | 45# steel |

| Diameter of Shaft | 70-80 mm |

| Voltage | 380V 50Hz 3 phases |

| Wall Thickness of Main Forming Machine | 12-18 mm steel plate |

| Main Forming Machine Body | 300-400 mm H steel |

| Motor Power | 4-7.5 kW |

| Weight | About 5-15 T |

| Custom | According to customer requirements |

Packing & Delivery

| Packaging Details | Main machine is nude, the computer control box is packed with a wooden frame. |

| Delivery Detail | 20 days |

Images

Related Products

Product Inquiry Form

Thanks your message successfully submitted.