Description

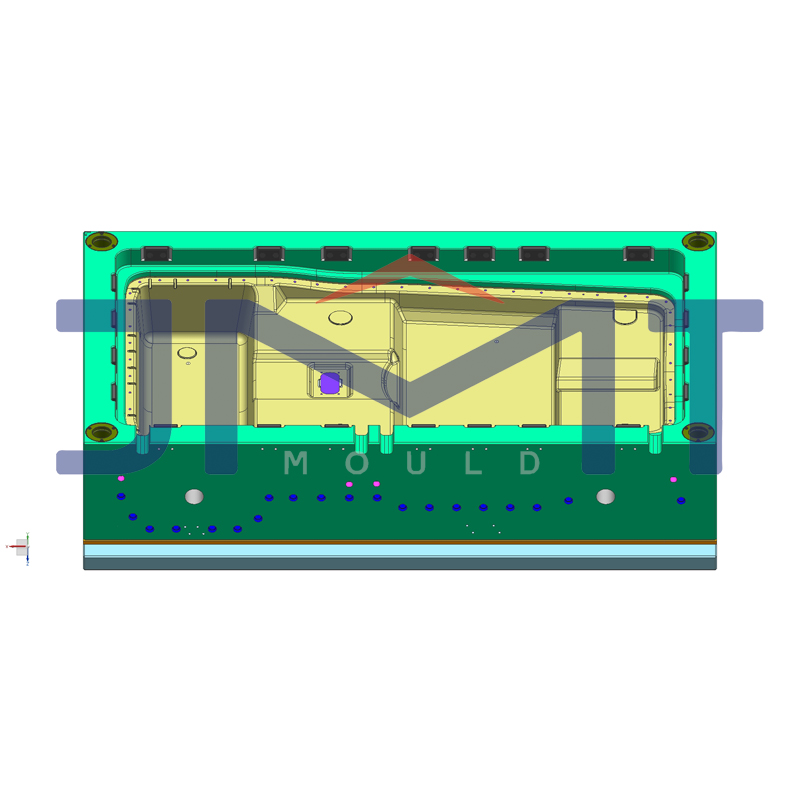

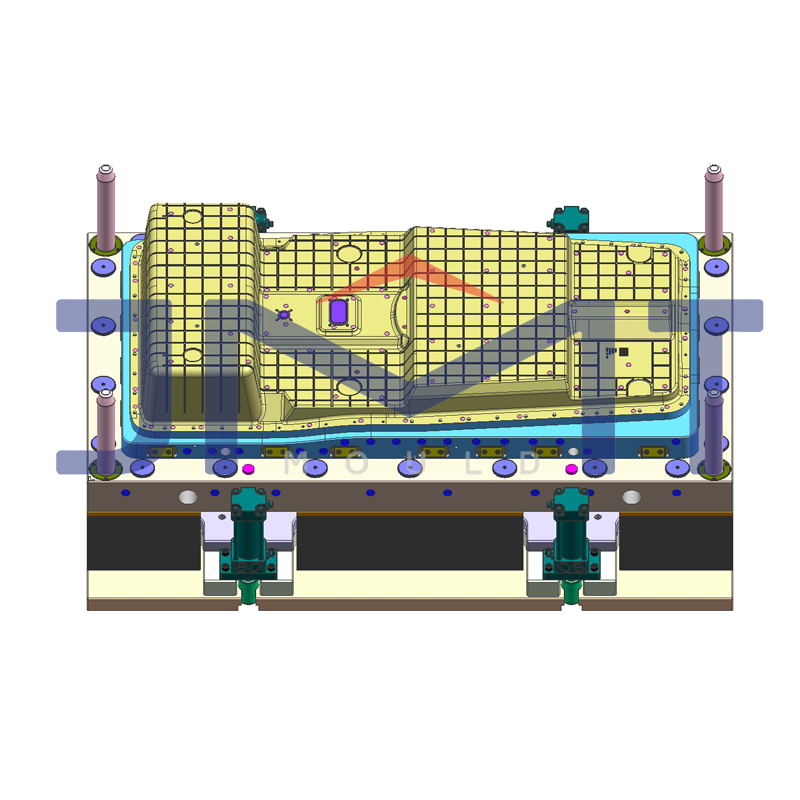

The Electrical Appliances Mould is a state-of-the-art mold maker designed for producing high-strength, complex parts using Sheet Molding Compound (SMC). This innovative manufacturing process utilizes a mixture of polymer resin, inert fillers, fiber reinforcement, catalysts, pigments, stabilizers, release agents, and thickeners, ensuring a superior quality outcome.

With SMC molding, manufacturers can efficiently create parts of various sizes, thanks to the use of matched metal dies mounted in a hydraulic molding press. The process involves precise placement of the material charge into the mold, followed by the application of heat and pressure—up to 2,000 psi—to achieve optimal results in just one to five minutes, depending on the part’s size and thickness. This method enables the incorporation of intricate features such as ribs, bosses, and inserts directly during the molding process.

Compression molded fiberglass parts produced with this technology boast excellent finished surfaces, remarkable part-to-part repeatability, and minimized trimming and finishing costs. Additional capabilities such as in-mold coatings and vacuum systems can enhance surface paintability, reducing the need for primer while allowing for customized color compounds.

Specifications

| Feature | Description |

|---|---|

| Material Type | Sheet Molding Compound (SMC) |

| Process Type | Compression Molding |

| Pressure Applied | Up to 2,000 psi |

| Cycle Time | 1 to 5 minutes |

| Customization | Color compounds available |

| Surface Finish | Excellent finished surfaces with minimal trimming costs |

Additional Information

- In-mold coatings available for enhanced surface paintability

- Vacuum systems in tools to further improve production efficiency